Categorys

Hot Product

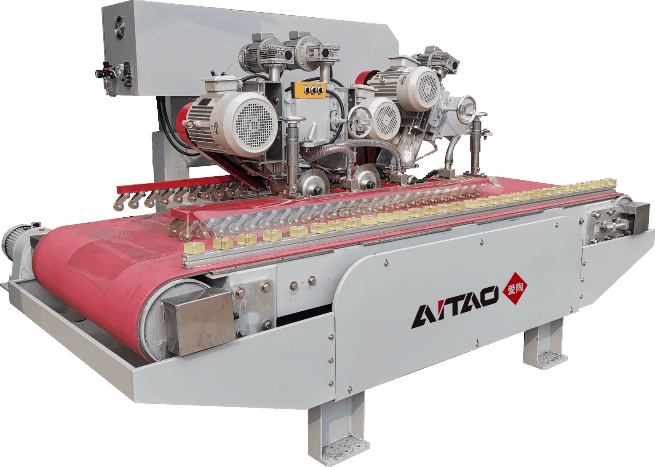

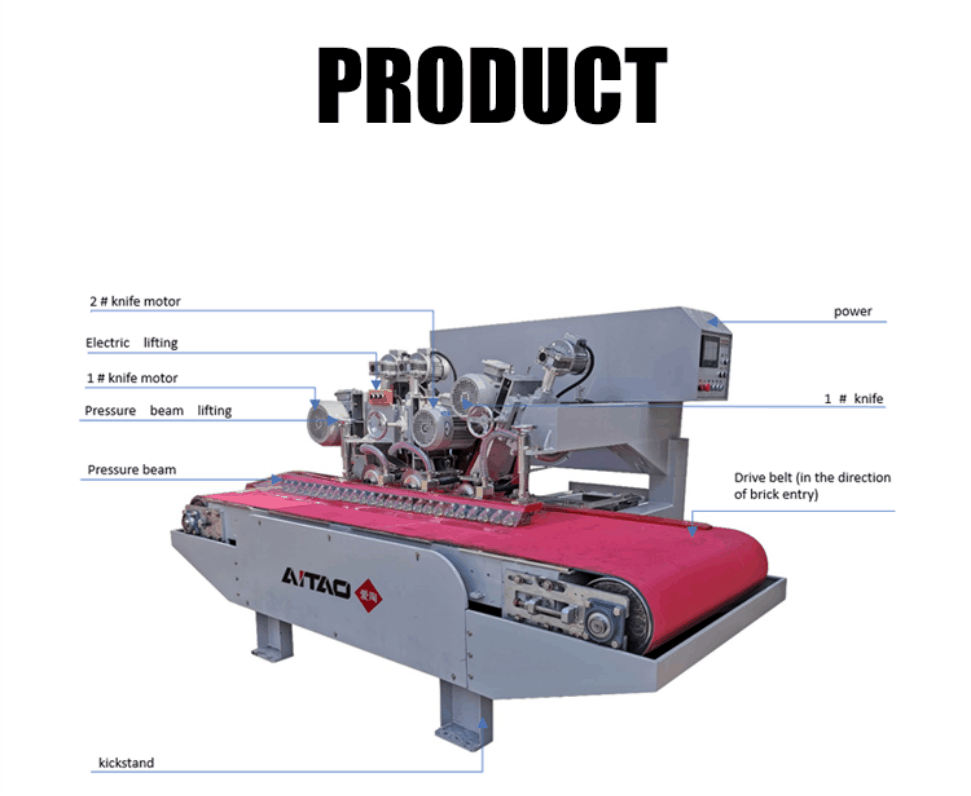

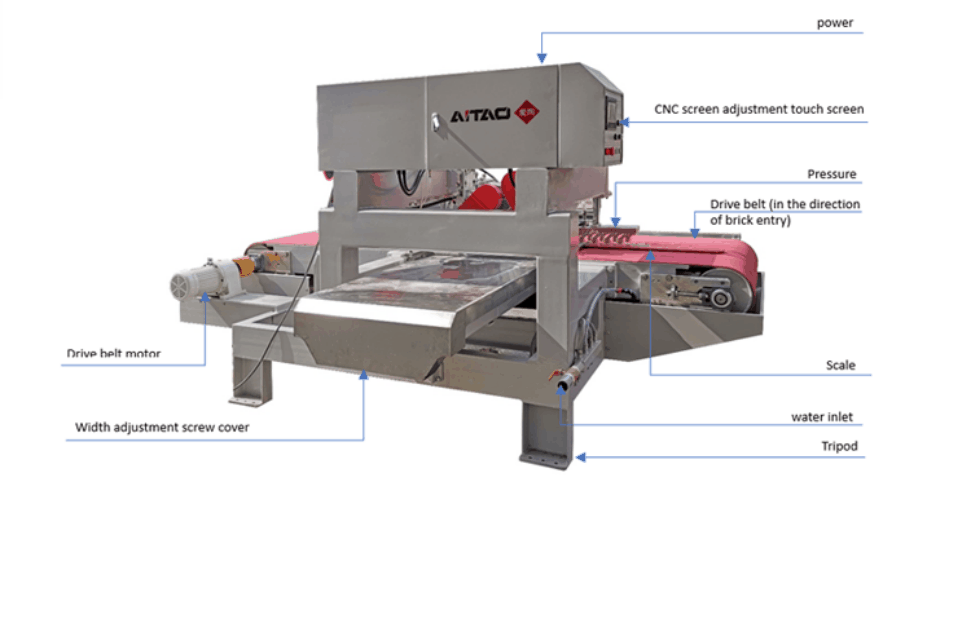

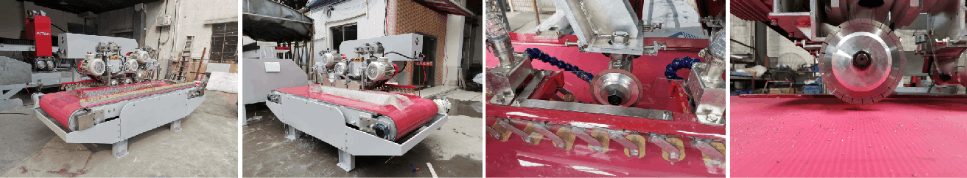

ATS-3 1800 Automatic CNC continuous tiles cutting Machine

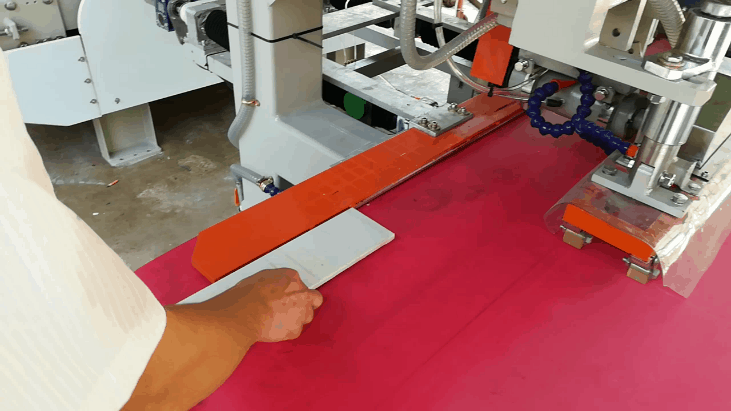

ATS-3/1800 Three Blades CNC Sintered Stone Cutting Machine is AITAO machinery in combination with the demand of the market,batch cutting, research and development production of a large size sintered stone cutting machine.

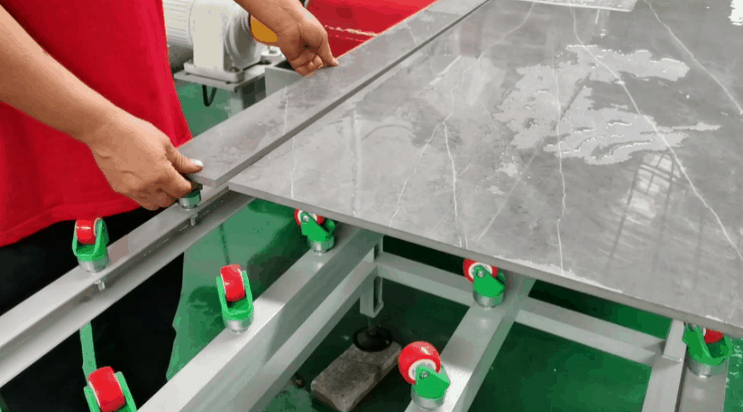

It can cut a piece of 900 * 1800 mm sintered stone into 900 * 900 mm or 450 * 1800 mm, cutting size can be set in the numerical control which display the cutting size. The cutting precision can be controlled within 0.1 mm.

ATS-3/1800type automatic cutting machine is High-speed batch cutting use to cutting big ceramic tile slab or sintered stone.

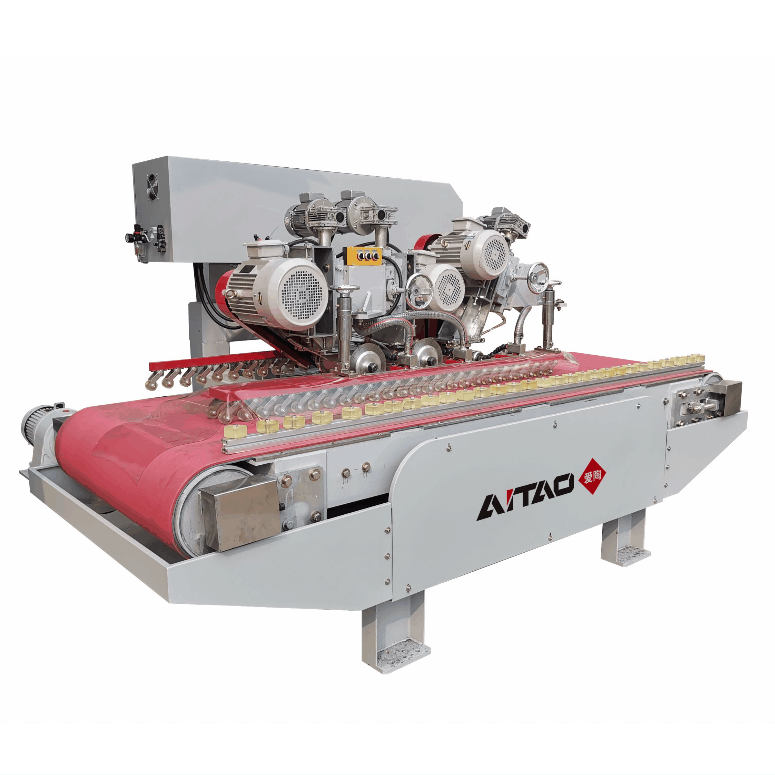

EQUIPMENT PARAMETERS

|

modle |

Belt width |

Speed convey speed |

modle |

modle |

Power of main shaft |

|

/ |

mm |

m/min |

mm |

mm |

kw |

|

ATS-3/1800 |

1000 |

2.5~7.5 |

φ120 |

φ180x60 |

4+4+5.5(kw) |

|

Power |

Working width |

working thickness |

Total power

|

Size

|

weight |

|

Kw |

mm |

mm |

kw |

mm |

kg |

|

0.37 |

50~1800 |

6~20 |

16.25 |

2965*2395*1750

|

2500 |

MAIN FEATUES

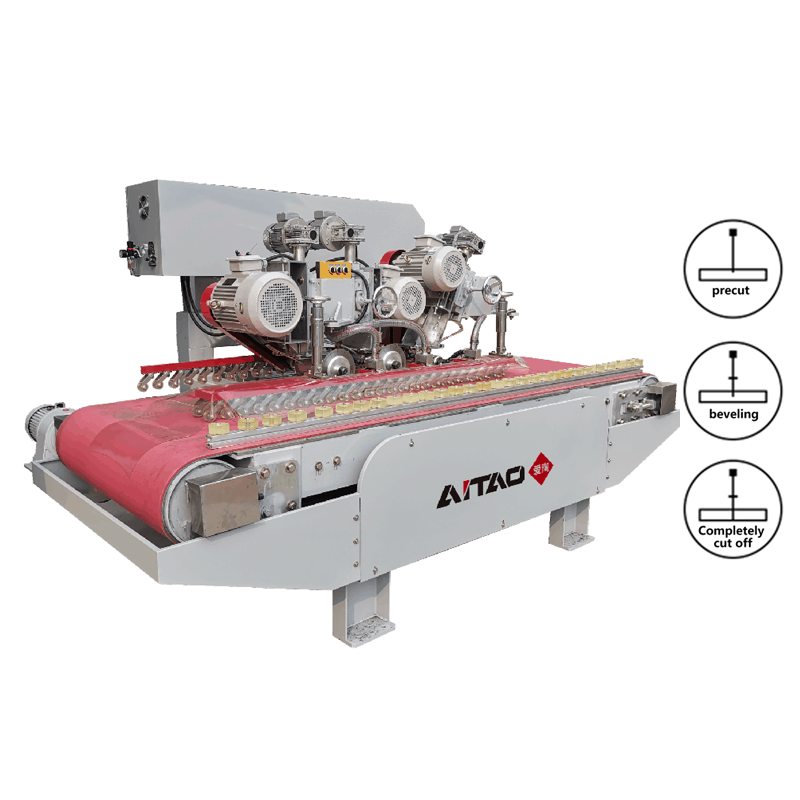

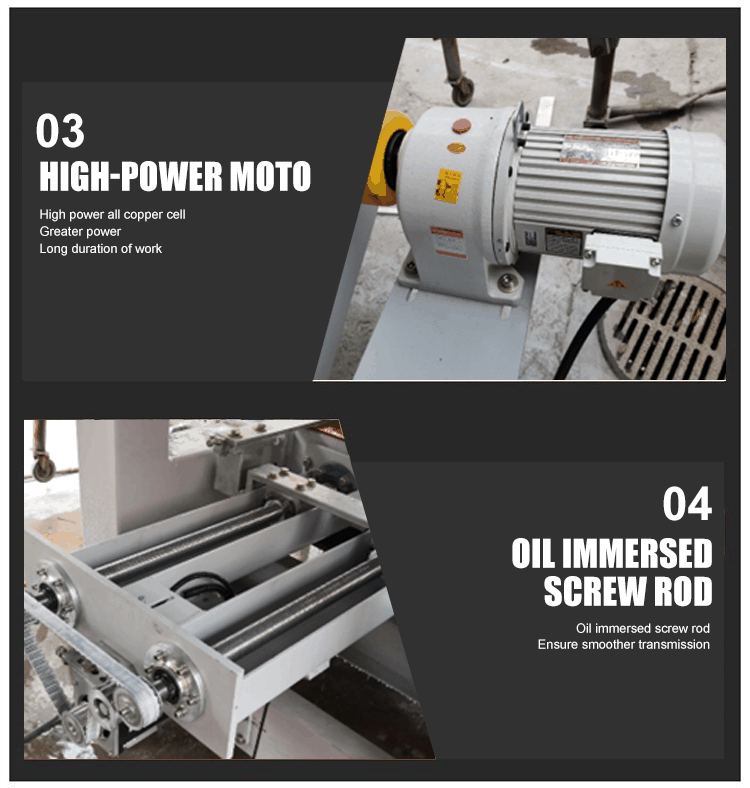

1. GOOD CUTTING STABILITY PERFORMANCE

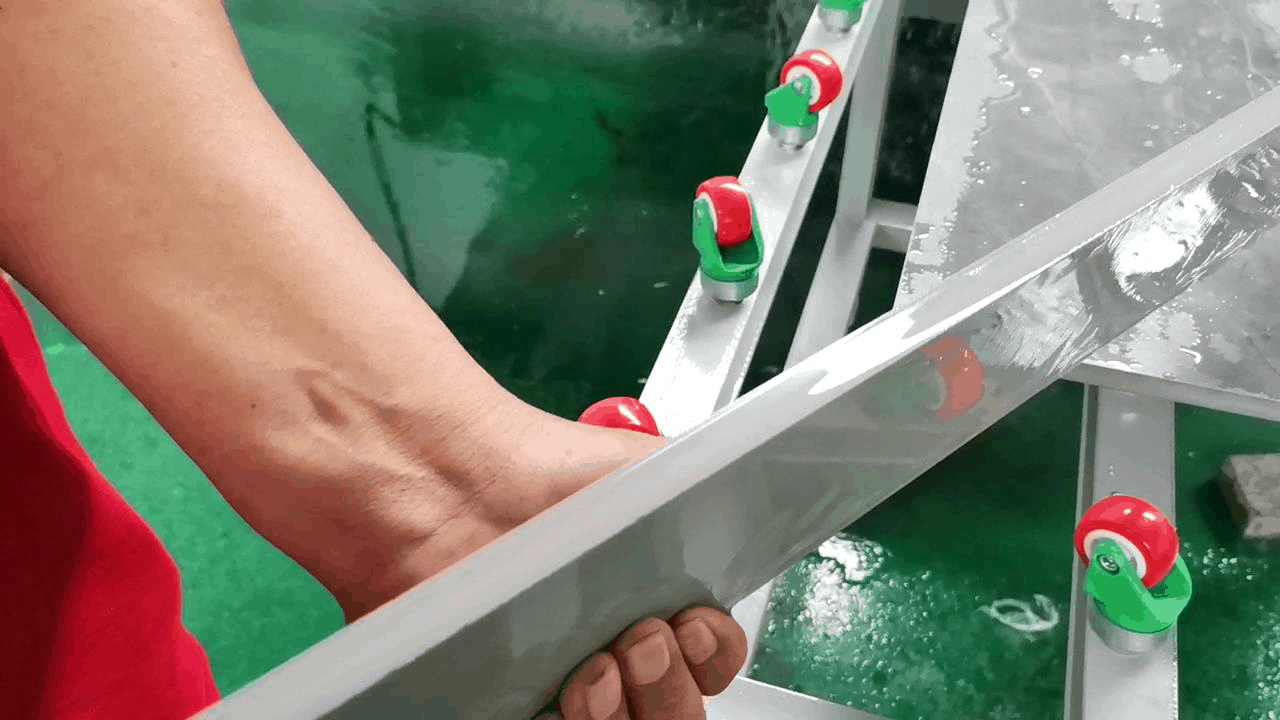

Automated ceramic tile processing equipment effectively alleviates the problem of cutting edges, providing a stable cutting speed, a straight cutting surface that is not prone to bouncing edges, and reducing the generation of vibration during cutting

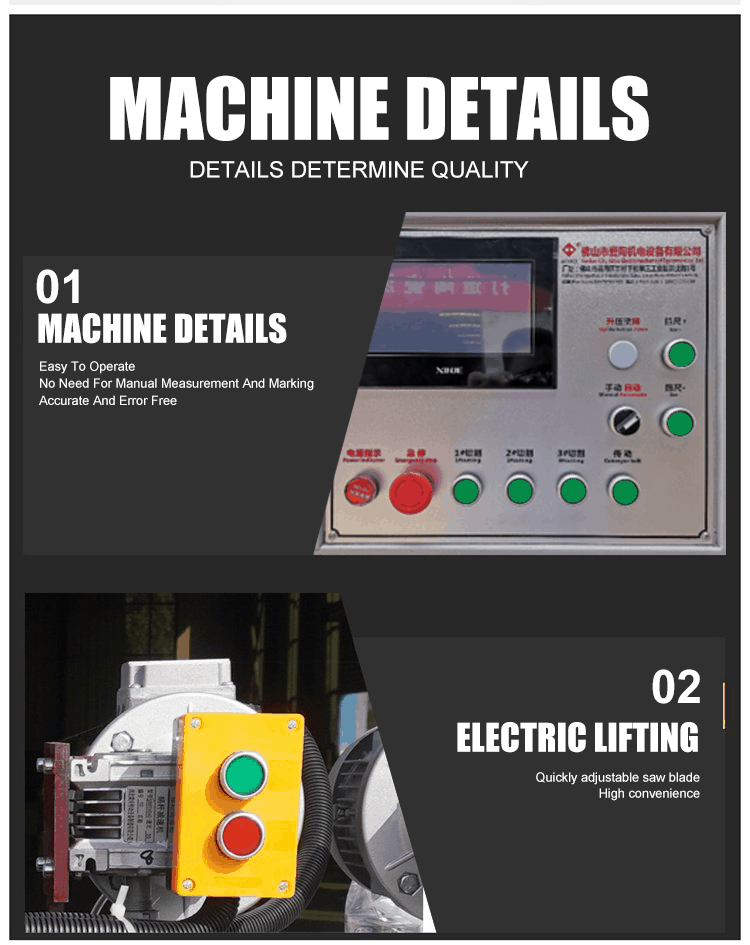

2. HIGH CUTTING ACCURACY

Solved the problem of low precision during cutting, and adopted a CNC system to control the size, which can control the cutting accuracy within 0.1mm;

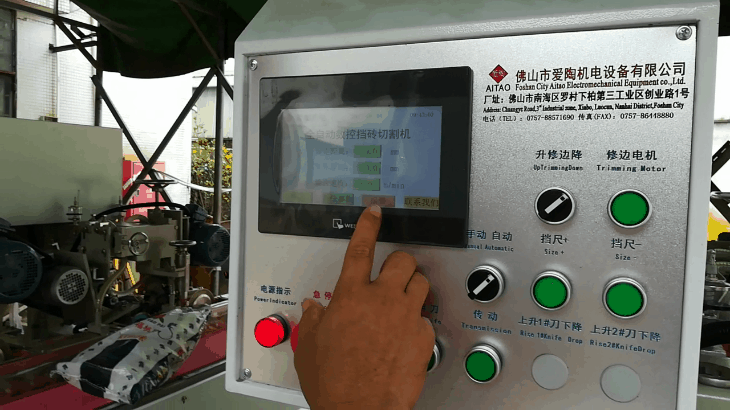

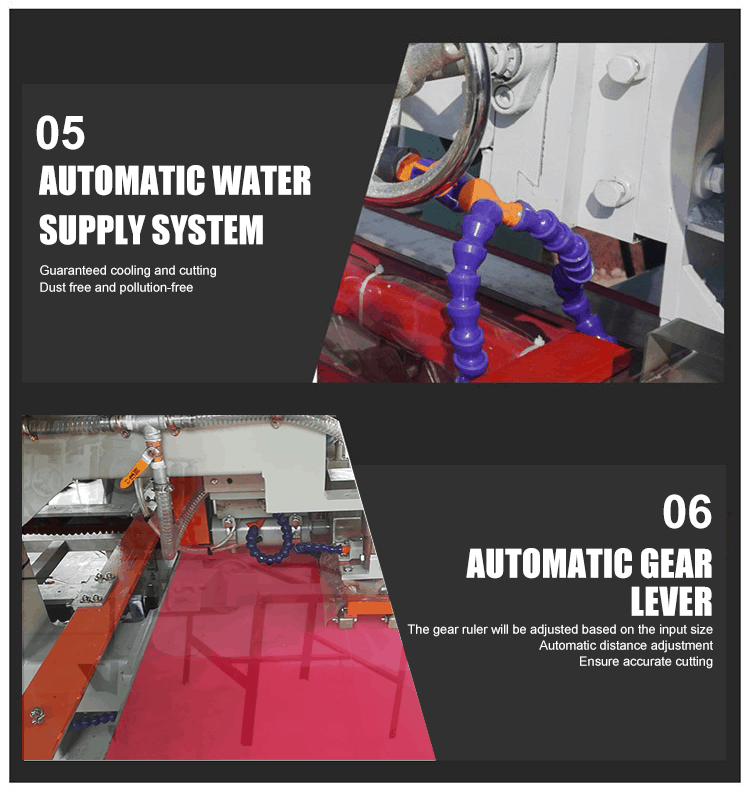

3. NO NEED FOR MANUAL SIZE ADJUSTMENT

Successfully solved the problem of automatic control of mechanical cutting dimensions. Simply input the size parameters to be cut on the control panel, and the baffle will automatically move to the desired position, bidding farewell to the era of workers measuring dimensions with straight scales;

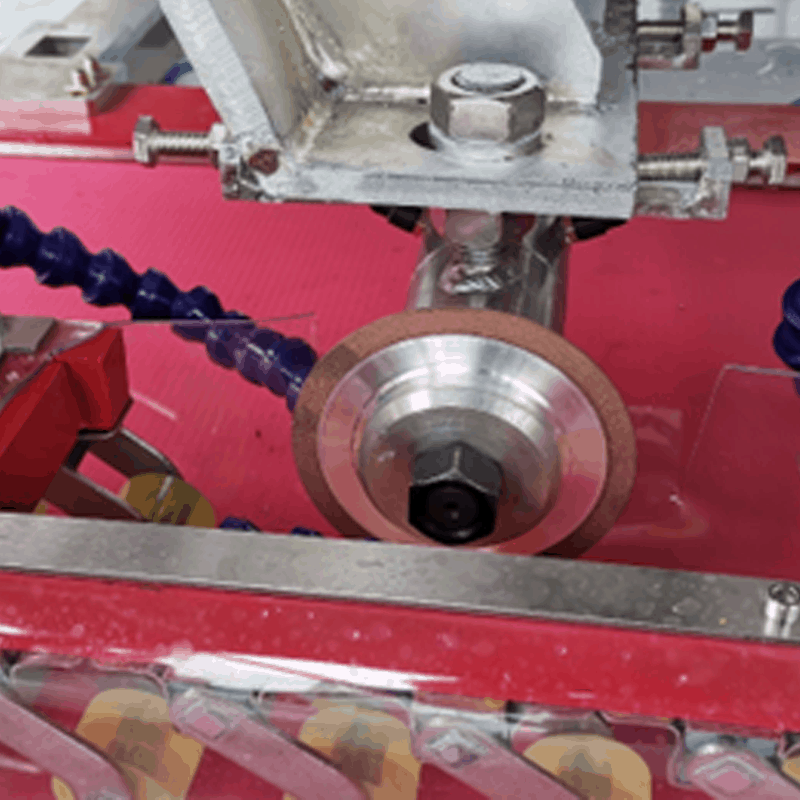

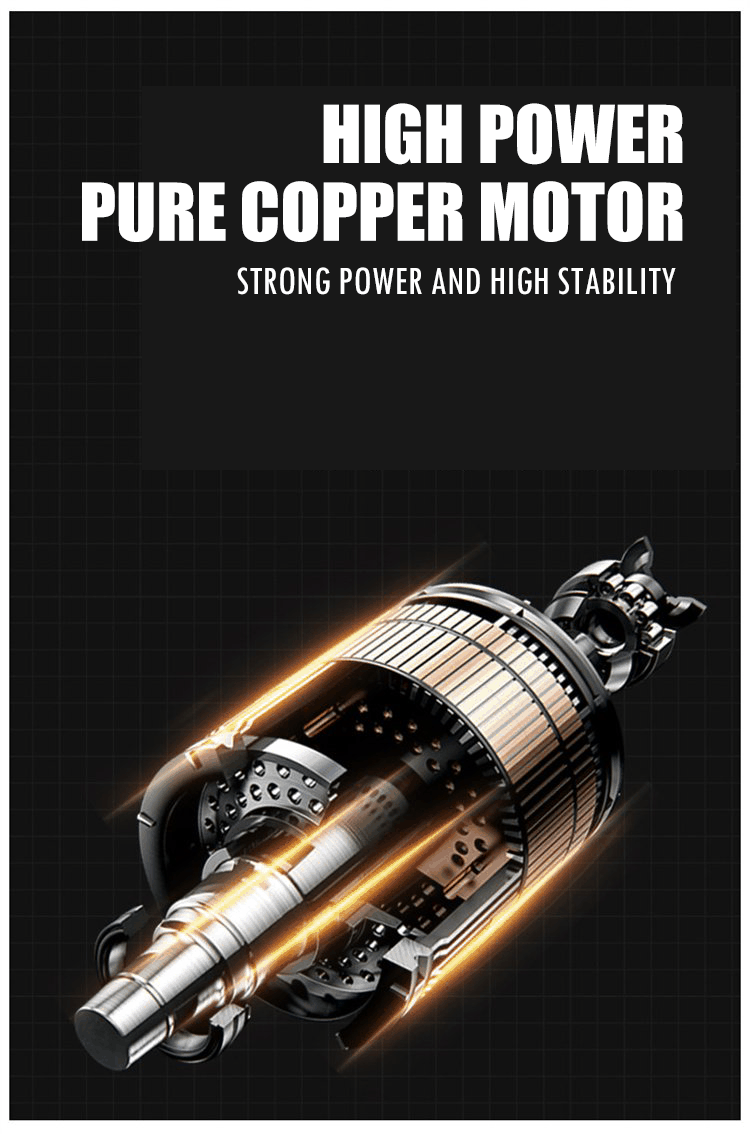

4. LONG SERVICE LIFE

A brand new design concept, with normal maintenance and upkeep, can reach a lifespan of ten years;

5. REDUCED COSTS

Reduced cutting costs, electricity costs, mechanical costs, and maintenance costs. Under normal use, the entire machine does not need to be replaced or added with any consumable parts, resulting in low maintenance costs and good energy-saving performance;

6. HIGH EFFICIENCY, GOOD EFFECT

Improved production efficiency. One fully automatic CNC ceramic tile cutting machine can handle four manual cutting machines, and one person can handle four people. The speed is increased by four times, saving a lot of labor. Moreover, CNC machining is more precise than manual labor, and the processing effect is far better than manual labor.

7. CONVENIENT AND FAST SIZE ADJUSTMENT

This machine is easy to operate and can be operated without too much experience. It can be adjusted to any size you need in 5 seconds.

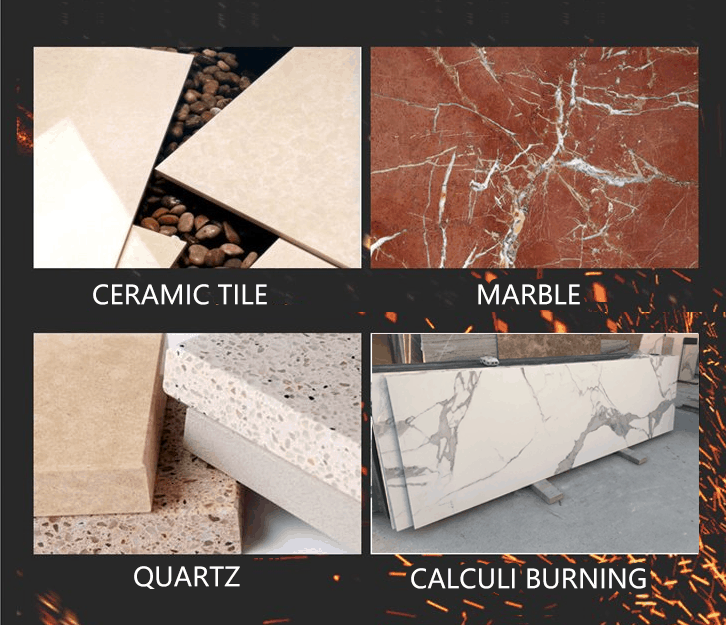

APPLICATION

EQUIPMENT CASES