Categorys

Hot Product

Products

In today's modern world, industrial processes require advanced machinery and equipment to ensure efficiency and productivity.

Water jet cutting machines, ceramic processing equipment, sintered stone processing equipment, and automation equipment for ceramic tile packaging production lines are the four main categories of equipment used in various industries.

Water Jet Cutting Machine

A water jet cutting machine is a versatile tool used in various industries for precise cutting and shaping of different materials. It utilizes a high-pressure stream of water mixed with abrasive particles to create clean and accurate cuts. This equipment is commonly employed in industries such as aerospace, automotive, and manufacturing. Water jet cutting machines provide remarkable precision and versatility due to their ability to cut through a broad range of materials, including metals, ceramics, and composites.

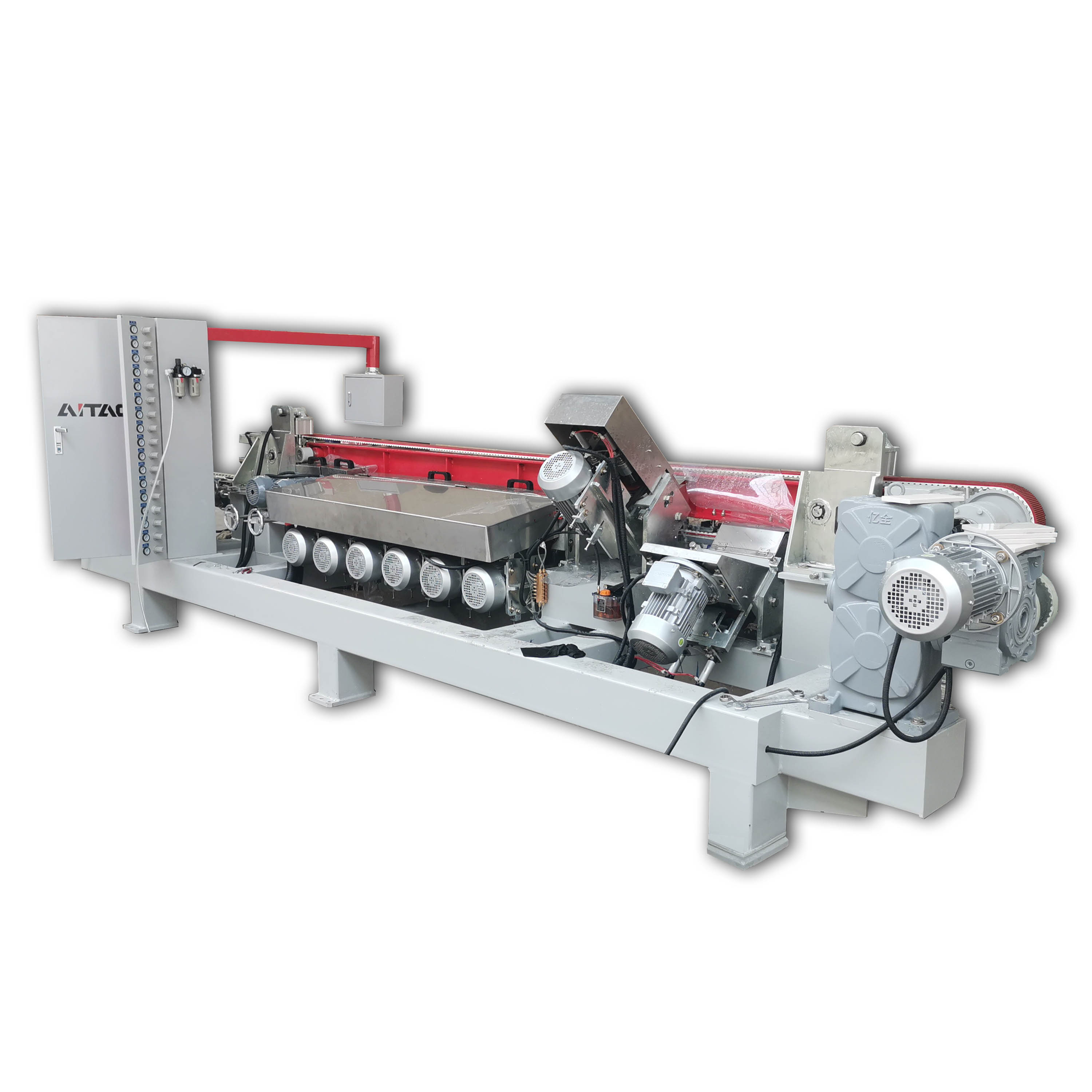

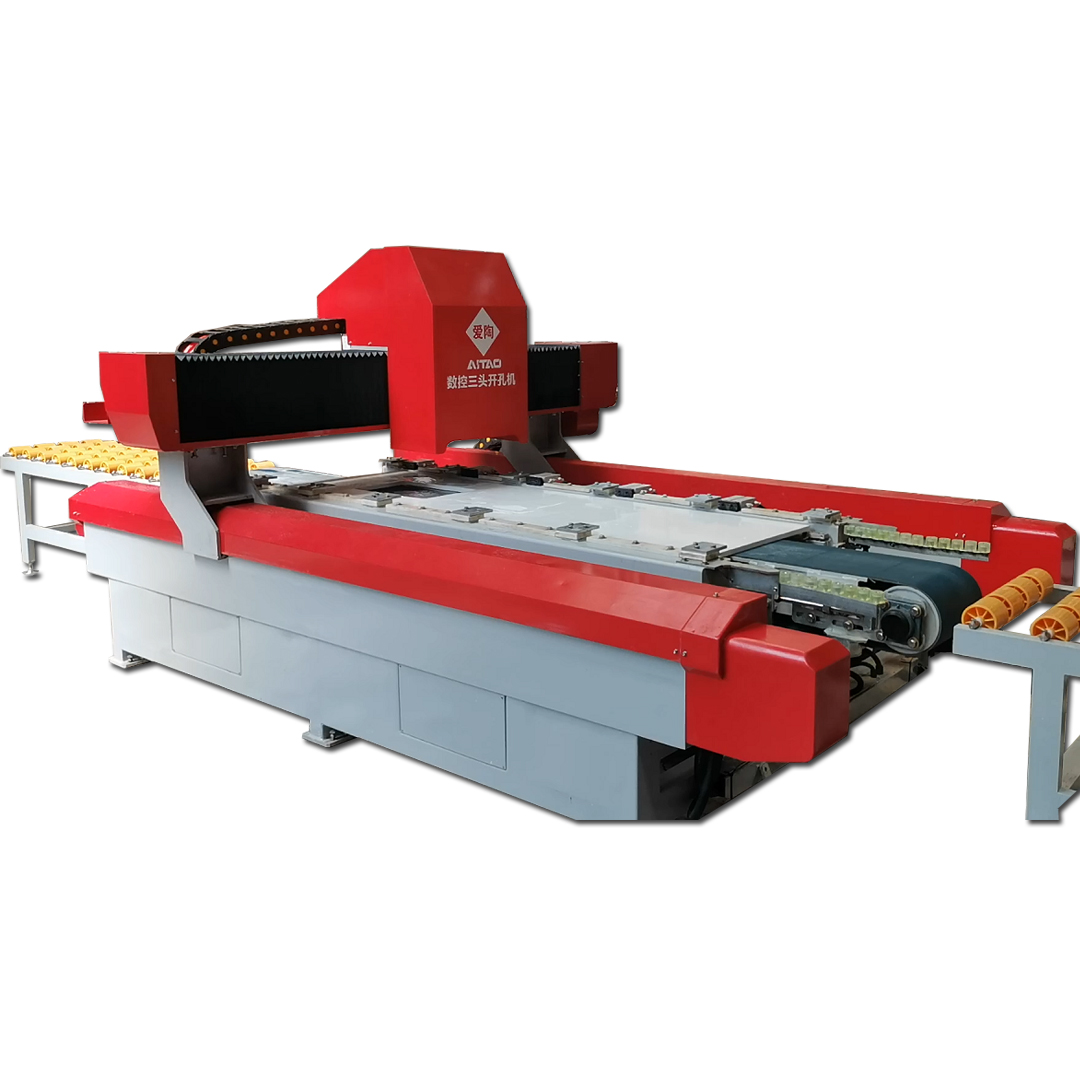

Ceramic Processing Equipment

Ceramic processing equipment plays a vital role in the production of ceramic products. From raw material preparation to shaping and firing, this equipment streamlines the entire manufacturing process. The main functions of our products are: trimming, grooving, chamfering, arc grinding, and arc polishing. In addition, it can be combined with a two-knife CNC ceramic cutting machine and a two-spindle tile cutting machine to process tile skirting boards and tile stair treads in batches.

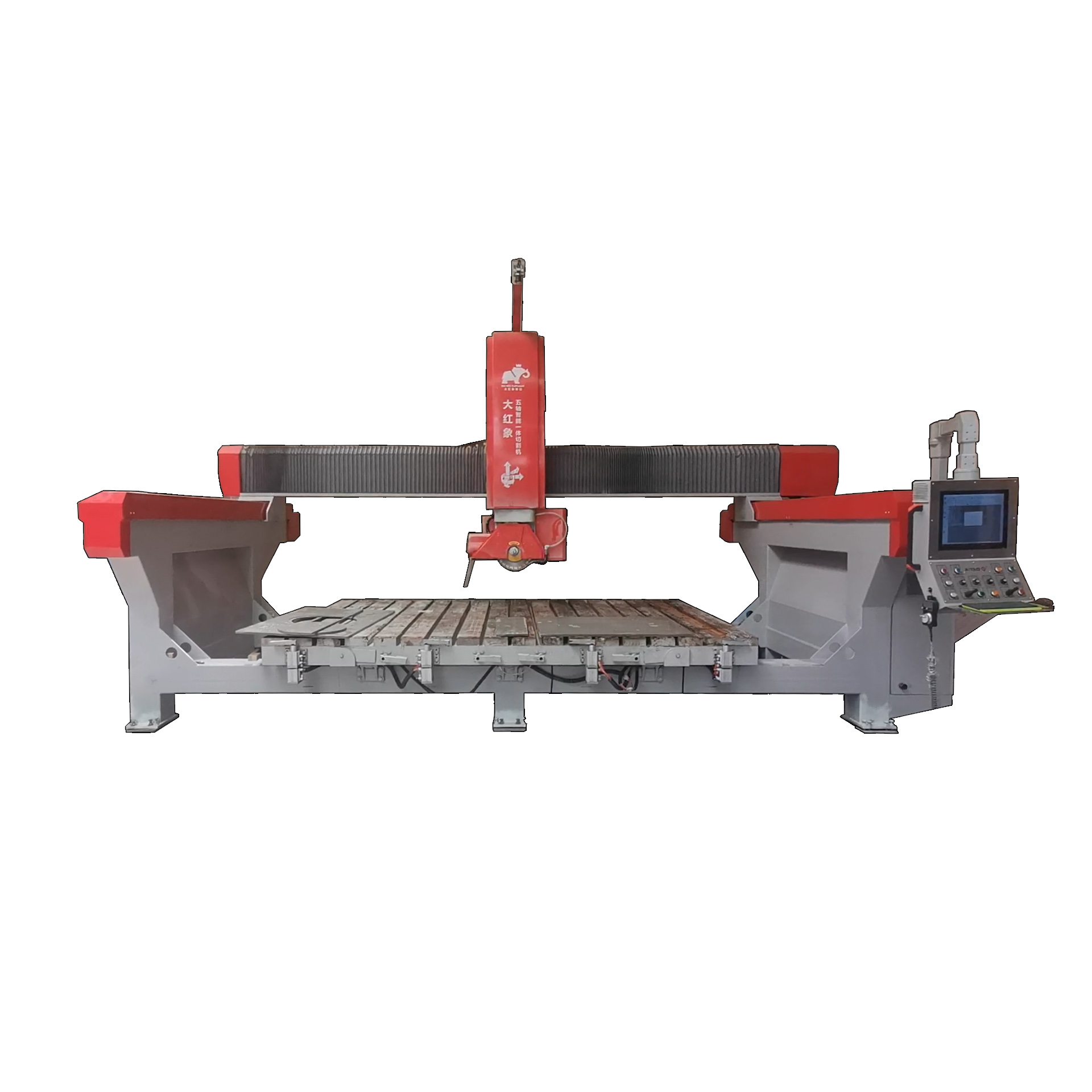

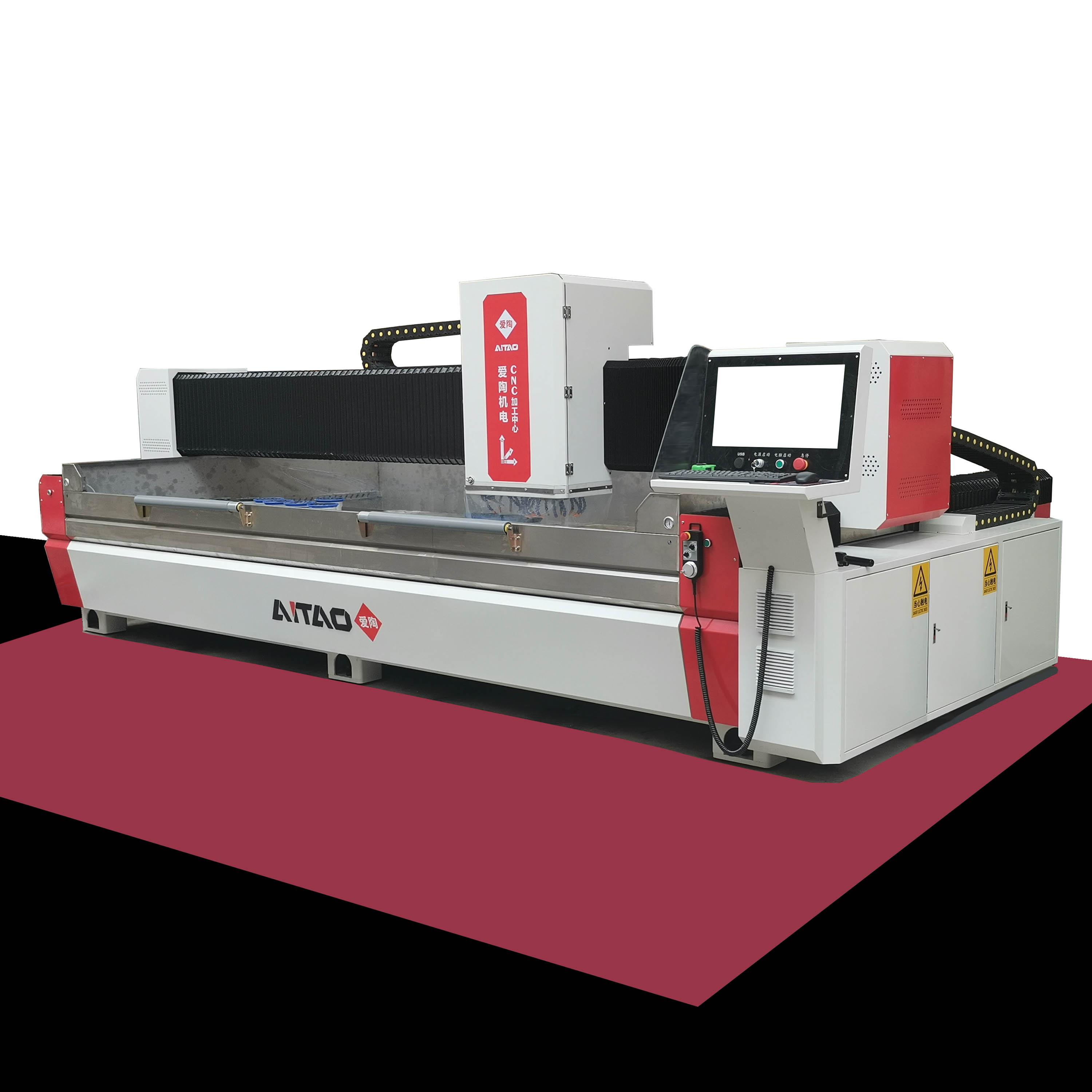

Sintered Stone Processing Equipment

Sintered stone is a durable and versatile material used in various architectural and design applications. Sintered stone processing equipment enables the fabrication and finishing of this material, ensuring its suitability for different projects. Sintered stone processing equipment allows for the creation of stunning and durable surfaces.

Automation Equipment and Ceramic Tile Packaging Production Line

The automation of industrial processes has revolutionized manufacturing efficiency. Automation equipment, combined with a ceramic tile packaging production line, offers increased productivity and cost-effectiveness for ceramic tile manufacturers. This equipment includes robotic systems, conveyor belts, and packaging machinery. Robotic systems automate tasks such as tile stacking and palletizing, reducing labor costs and increasing output.

If you are interested in it, click the link at the bottom for more product details!