Categorys

Hot Product

Five Axis CNC Wash Basin Water Knife Cutting Machine

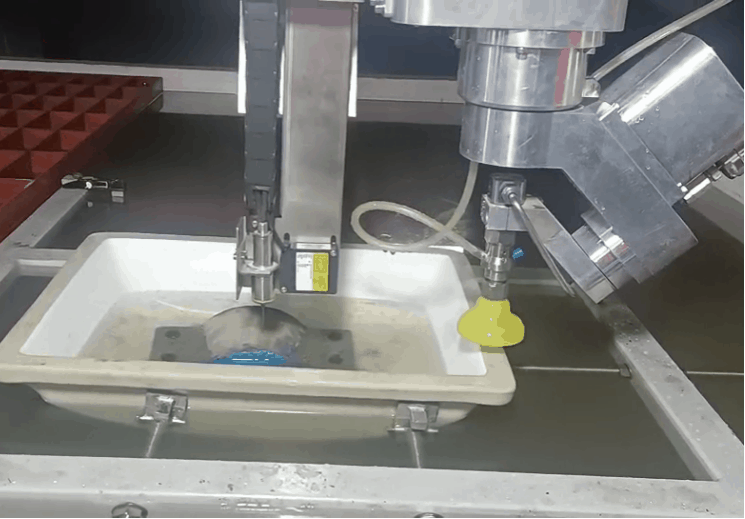

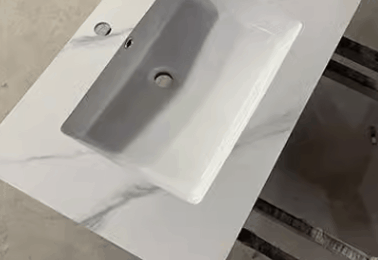

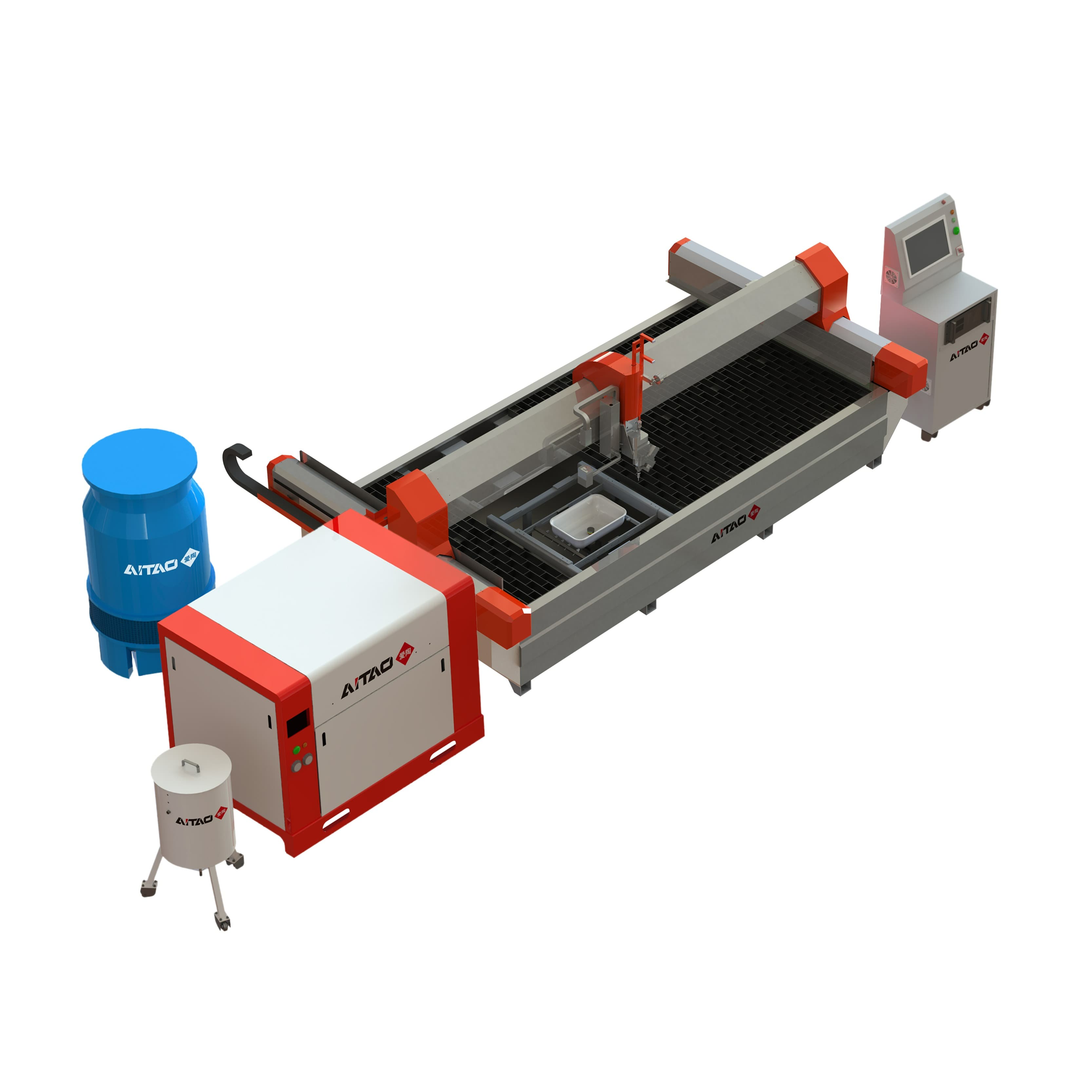

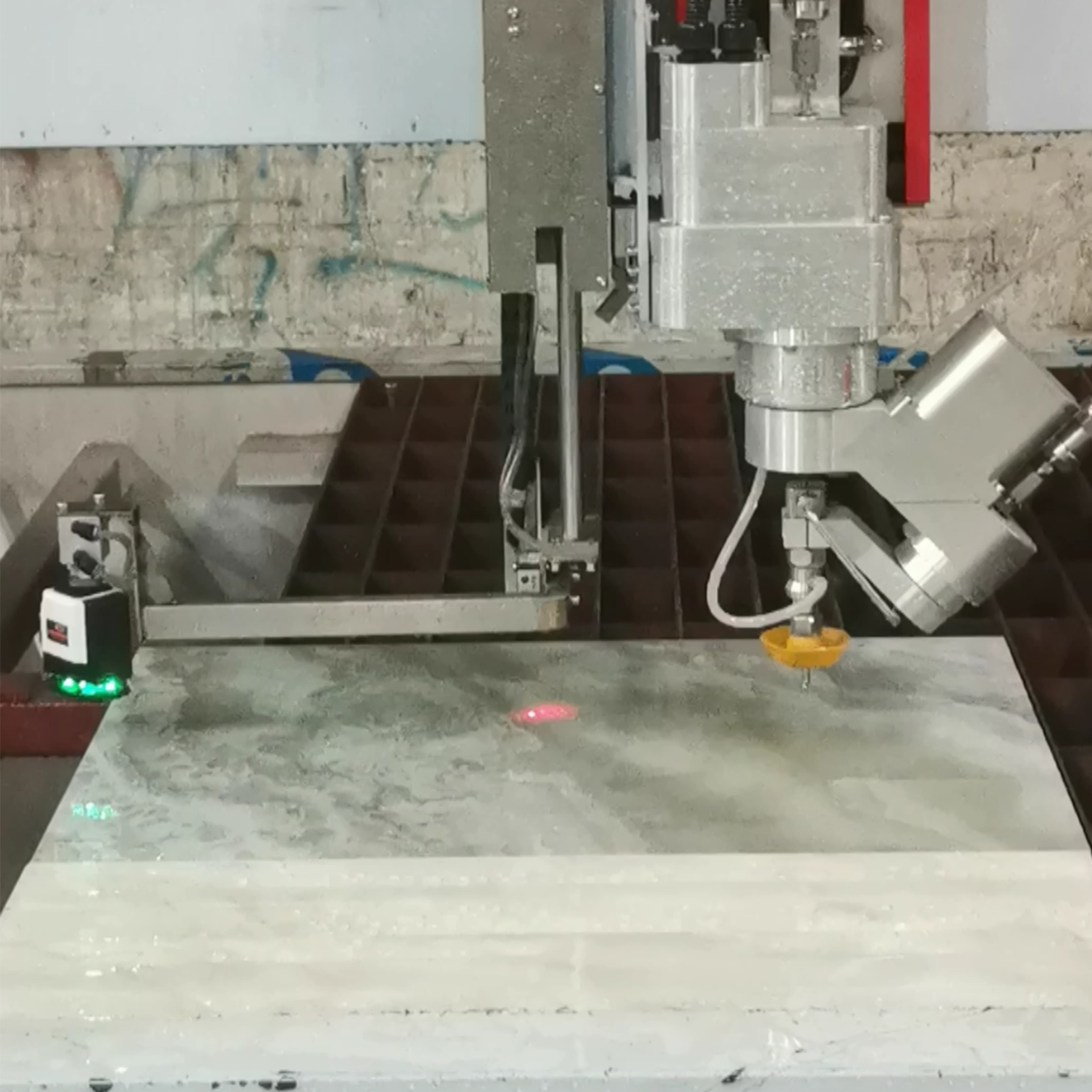

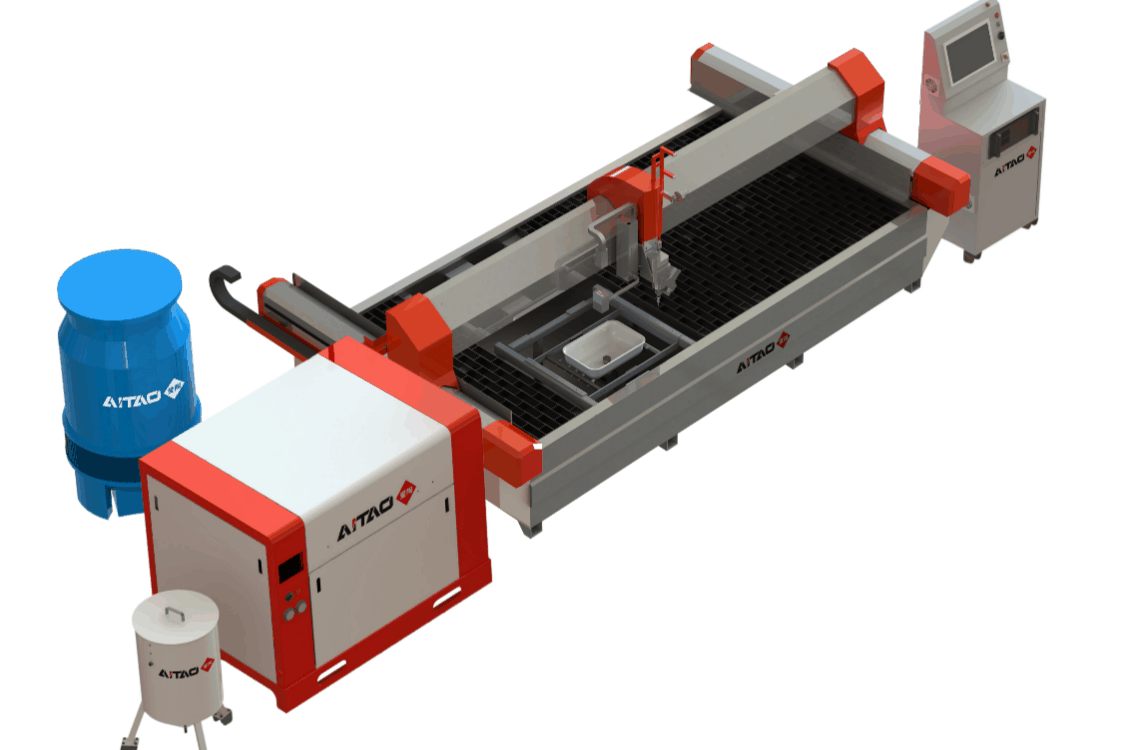

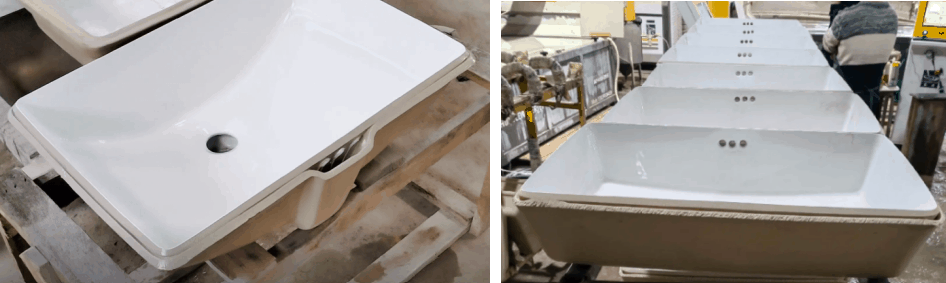

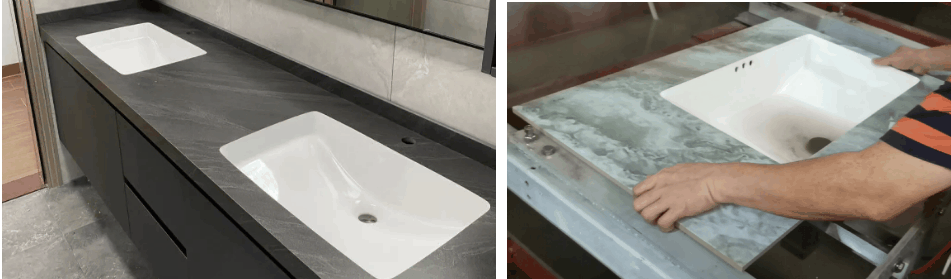

The AC five axis water jet visual photo taking and cutting system is a new type of equipment developed by Aitao Electromechanical Co., Ltd. for the production of "no encounter wash basin" cutting. The equipment applies advanced technology of precise imaging and automatic generation of cutting paths, with good cutting quality and fast speed, greatly improving cutting efficiency.

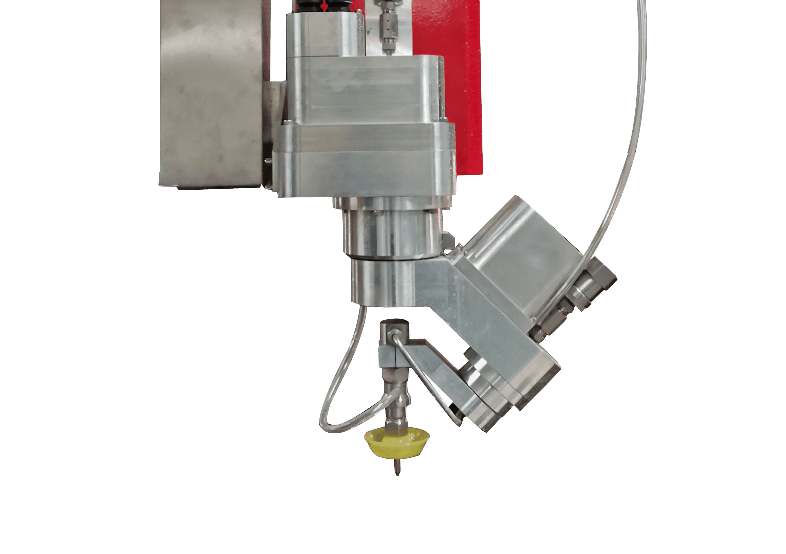

This water knife consists of an AC five -axis water knife+visual camera system+probe+imported laser displacement. The ultra -high -definition camera instrument is combined with advanced algorithm and a precise graphics generation system, which greatly reduces the scanning positioning time and improves the production of bathroom basin at full speed. Efficiency, a pot of one -board support cutting mode, one -click photo, and implemented simultaneously. Automatic flat, automatic background stroke CAD graphics, after forming graphics, automatically add to automatic cutting. During the cutting period, you can enter the size parameters of the outer frame panel according to the order drawing drawing, the ceramic basin cutting is completed, and the panel graphics cut is automatically generated. This high -precision and fast -efficiency cutting method is the highest configuration of seamless pot cutting process.

Main Features

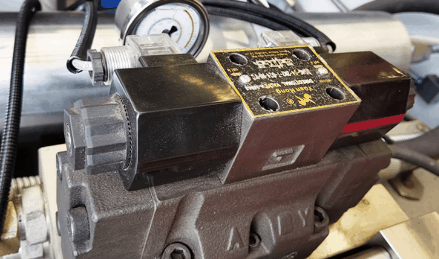

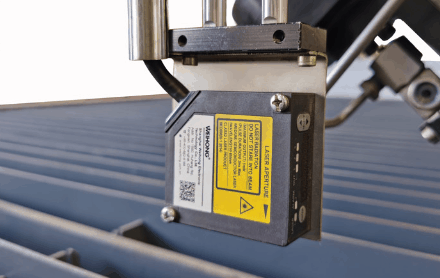

1. This water jet consists of an AC five axis water jet, a visual camera system, a probe, and a laser displacement sensor.

2. The ultra-high definition camera, combined with advanced algorithms and precise graphics generation system.

3. One pot, one board matching cutting mode, one click photography, synchronized implementation.

4. Automatic leveling, automatic backend stroke CAD graphics, automatic cutting after forming graphics

5. During the cutting process, the size parameters of the outer frame panel can be input according to the order drawings.

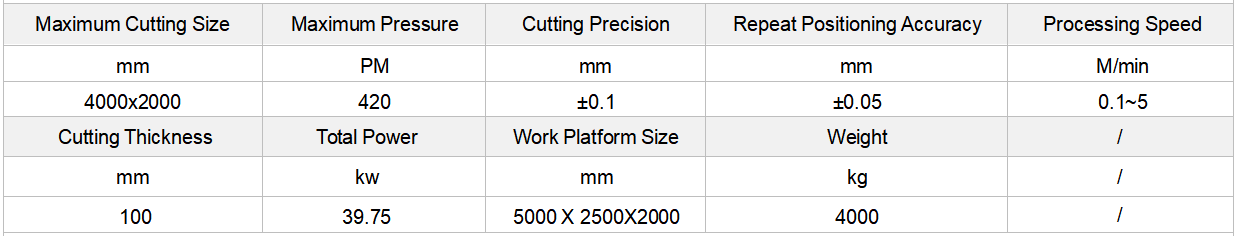

Equipment parameters

Application

Main Equipment Description

cutting platform specifications

AT3020:3000x2000(mm)

AT4020 : 4000x2000(mm)

Cantilever cutting platform specifications:

AT2515:2600 x 1600(mm) AT3015:3100 x 1600(mm)

Cutting accuracy: ± 0.1mm

Repetitive accuracy: ± 0.05

Moving parts: Taiwan "ABBA" or "TBI"

Linear guide rail/ball screw "oil bubble type

X-axis running speed: 0-5000mm/min; 1.5KW

Y-axis running speed: 0-5000mm/min; 1.5KW

Z-axis running speed: 0-1000mm/min; 0.40KW

A-axis rotation angle: ± 70 degrees; 0.20KW

C-axis rotation angle: infinite; 0.20KW

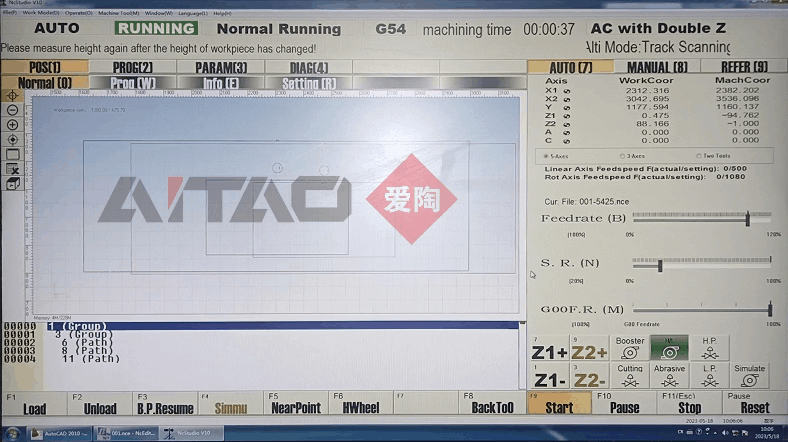

Control system:CNC driver;

Industrial control computer; JAWJ cutting software (NC Studio V-9.38)

Based on Win7 32-bit, genuine Shanghai Naikai Ncstudio

Operation interface: Chinese/English can be switched freely

Z-axis stroke: 110mm

Centralized lubrication system makes machine tool operation more reliable

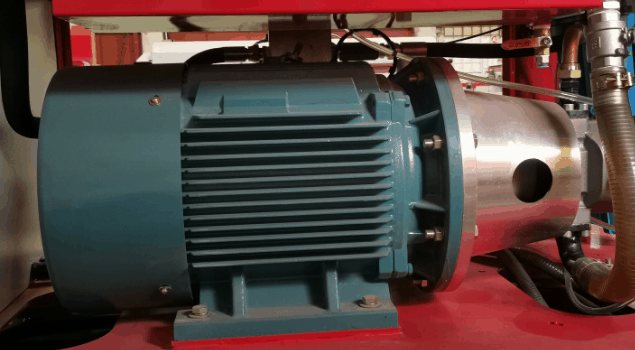

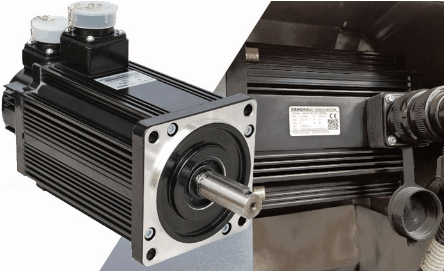

Servo motor: Weizhi AC servo

Power supply: 220V/380V/50HZ

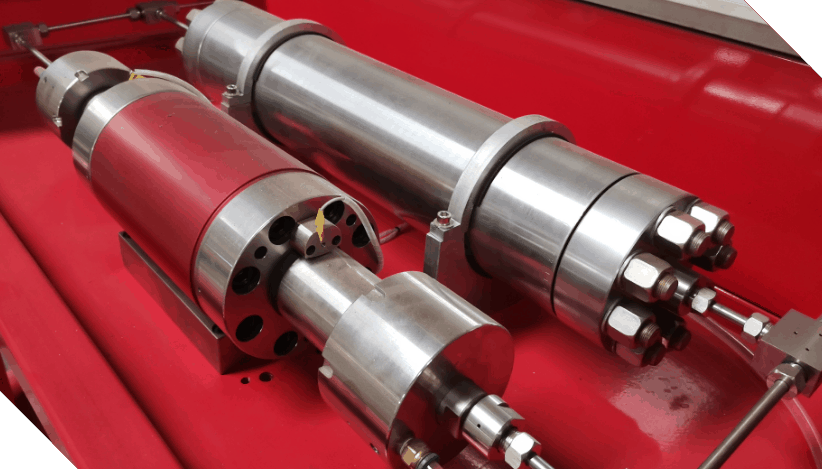

|

model |

AT420 |

AT420Ⅱ |

AT450 |

|

Max.pressure :(Mpa) |

420 |

420 |

380 |

|

Long time working pressure:(Mpa) |

280-380 |

280-380 |

280-380 |

|

Intensifier ratio :(L/min) |

1:20 |

1:20 |

1:20 |

|

Max.flow rate :(L) |

3.7 |

4.6 |

6.8 |

|

Inlet pressure :(Mpa) |

0.4 |

0.6 |

0.6 |

|

Max.rifice size :(mm) |

0.33 |

0.35 |

0.35 |

|

Max.pump flow :(L/min) |

105 |

148 |

148 |

|

Max.pump pressure : (Mpa) |

31.5 |

31.5 |

31.5 |

|

Max.pump pressure : (L) |

120 |

120 |

120 |

|

Power supply : (Kw) |

30-37 |

37-45 |

37-45 |

The automatic sand supply system uses air pressure to deliver sand from the water knife to the cutting head

Inside the small sand bucket, which reduces the labor intensity of operators, and there is no need to stop the machine when adding sand,

Improved work efficiency and reflected the automation level of CNC water jet knives.

Introducing international advanced technology and designing according to international safety standards, ensuring safety and reliability.

Detail Images

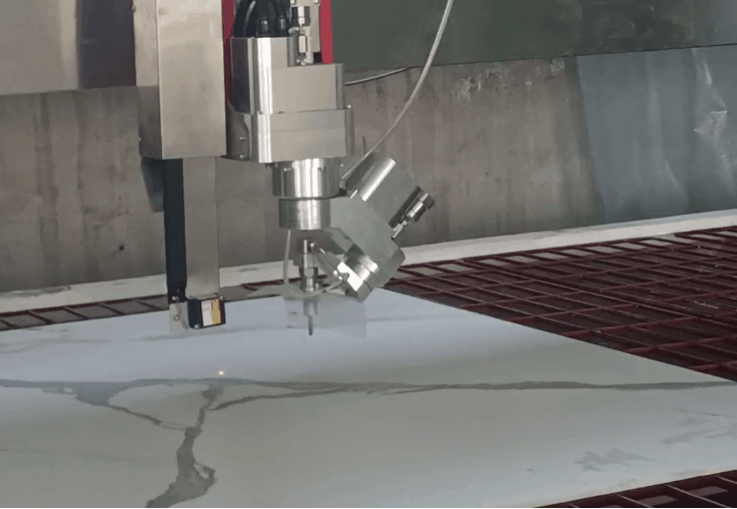

AC Five Axis Cutting System

The Aitao five axis water jet cutting system has added an A-axis (winding) on top of the standard three axis (XYZ)X-axis rotation) C-axis rotation (around Z-axis rotation) can achieve large angle deflection, with a maximum deflection angle of up toThe travel of the 75 Z axis is equivalent to that of a standard water jet.

Our Service

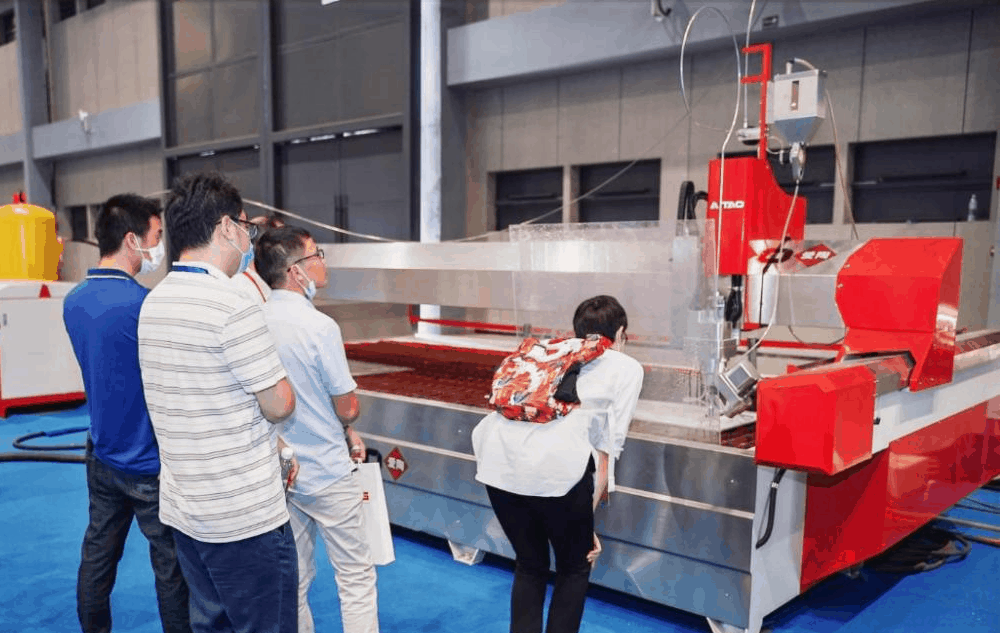

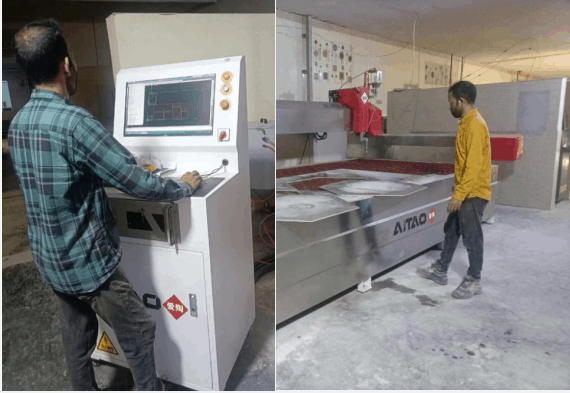

Equipment Cases