In the world of stone and countertop fabrication, the quest for the perfect cut has led to the development of sophisticated machinery designed to meet the industry's demanding precision needs. Among these innovations, the 5-axis CNC bridge saw stands out as a game-changer, especially for creating high-end kitchen countertops and intricate ceramic designs. This machine not only meets the industry's precision requirements but also caters to the growing trend for custom-designed stone features in modern homes. As we delve into the advantages of this cutting-edge technology, we'll see how it not only enhances the precision and efficiency of stone cutting but also opens up new possibilities for creative and complex designs that were once thought impossible.

Precision And Accuracy

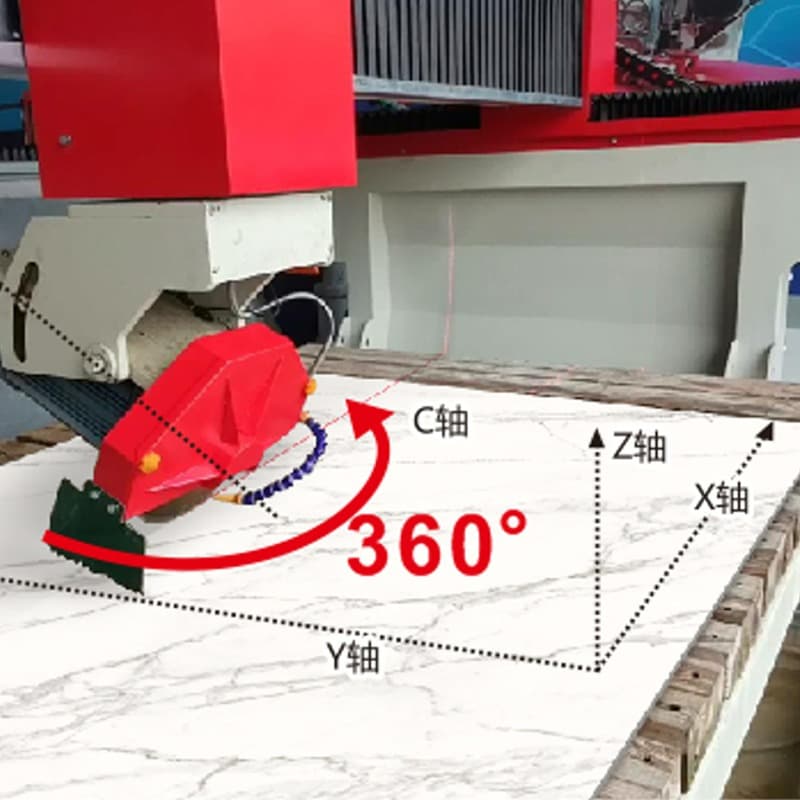

Precision is paramount in the stone fabrication sector, where even the slightest mistakes can result in costly waste and rework. The 5-axis CNC Bridge Saw excels in delivering unmatched precision. Its advanced technology and multi-axis capabilities ensure that every cut is executed with the utmost accuracy, which is particularly beneficial for high-end kitchen top ceramics and custom countertop designs. The machine's five-axis cutting capacity allows it to approach the material from different angles, guaranteeing that even the most complicated and precise cuts are done properly. Whether it's crafting complex curves, bevels, or mitered edges, this machine guarantees that each cut is made with exceptional accuracy. This level of precision reduces the need for additional manual finishing, saving time and resources while consistently delivering top-quality results.

Professional CNC bridge saw manufacturers

Increased Productivity

The efficiency and speed of a 5-axis CNC Bridge Saw increased production dramatically throughout the stone manufacturing process. Traditional cutting processes need frequent manual adjustments and tool changes, both of which can be time-consuming. In contrast, the CNC machine automates the entire cutting process, eliminating the need for frequent operator intervention. It can operate continuously, 24/7, ensuring a high level of productivity. This not only reduces labor costs but also accelerates project completion, allowing stone fabrication shops to take on more projects and meet tight deadlines with ease.

Versatility

A 5-axis CNC Bridge Saw's flexibility is a significant benefit for stone fabricating enterprises. It is designed to work with a wide range of stone materials, whether natural, manufactured, or composite. This adaptability makes it an ideal choice for shops dealing with diverse customer demands and a range of materials. Because of the machine's versatility, operators may safely tackle a wide range of tasks, from kitchen countertops to elaborate sculptures, knowing that the CNC Bridge Saw can meet each individual need.

5 Axis CNC Bridge Saw Manufacturers

Reduced Material Waste

Minimizing material waste is both ecologically ethical and cost-effective. Traditional stone-cutting procedures frequently result in significant offcuts and fragments that cannot be used economically for future projects. The 5-axis CNC Bridge Saw excels at optimizing material usage. Its precision means fewer offcuts, which translates into reduced material waste. This not only conserves resources but also lowers production costs, making it an economically sound choice for stone fabricators.

Enhanced Safety

Worker safety is the top priority in the stone fabrication industry. Traditional stone-cutting methods often pose significant risks due to the manual operation and the use of heavy machinery. The 5-axis CNC Bridge Saw greatly mitigates these hazards by automating the cutting process, which is especially crucial when handling large slabs for kitchen tops or intricate ceramic pieces. However, a 5-axis CNC Bridge Saw minimizes these risks by automating the cutting process. This reduces the potential for accidents, injuries, and operator fatigue. The machine has several safety measures, such as emergency stop mechanisms and safety interlocks, which offer an extra layer of protection.

Bridge Saw Cutting Machine Suppliers

Time And Cost Savings

A 5-axis CNC Bridge Saw provides significant time and cost advantages. As previously stated, the automation and accuracy of the equipment result in lower labor expenses. However, the advantages go beyond that. Reduced manual finishing requirements, fewer material offcuts, and shorter project completion dates all contribute to cost savings. This ultimately leads to improved profitability for stone fabrication businesses, making the 5-Axis CNC Bridge Saw a wise investment that pays off in both the short and long term.

Conclusion

The 5-axis CNC Bridge Saw has transformed the stone fabrication industry by offering a host of benefits. This advanced piece of machinery is not only a technological marvel but also a practical solution for businesses looking to improve their efficiency and deliver top-quality stone products. For those in the market for a premium 5-axis CNC bridge saw machine that can handle everything from stone countertop fabrication to precision cutting of kitchen top ceramics, AITAO is your go-to source. Partner with us to elevate your business to the forefront of the industry with cutting-edge technology and unparalleled performance.