Precision, speed, and efficiency are critical in contemporary manufacturing and stone cutting. The 5-axis CNC Bridge Saw is one technology that has transformed the stone-cutting sector. This sophisticated machine combines computer numerical control (CNC) technology with a multi-axis cutting system to produce precise and intricate cuts in various materials, most notably natural and engineered stone. In this article, we will explore the workings of a 5-axis CNC Bridge Saw.

What Is CNC Technology?

CNC machines are automated devices that are configured to conduct precise, high-accuracy jobs. These machines shape and manipulate materials by using computer software to operate various instruments such as cutters, drills, and routers. The primary advantage of CNC technology is its ability to repeat complex tasks with consistent precision, making it invaluable in industries that require high levels of accuracy and efficiency.

Automatic CNC Bridge Saw For Sale

What Is A 5-axis CNC Bridge Saw?

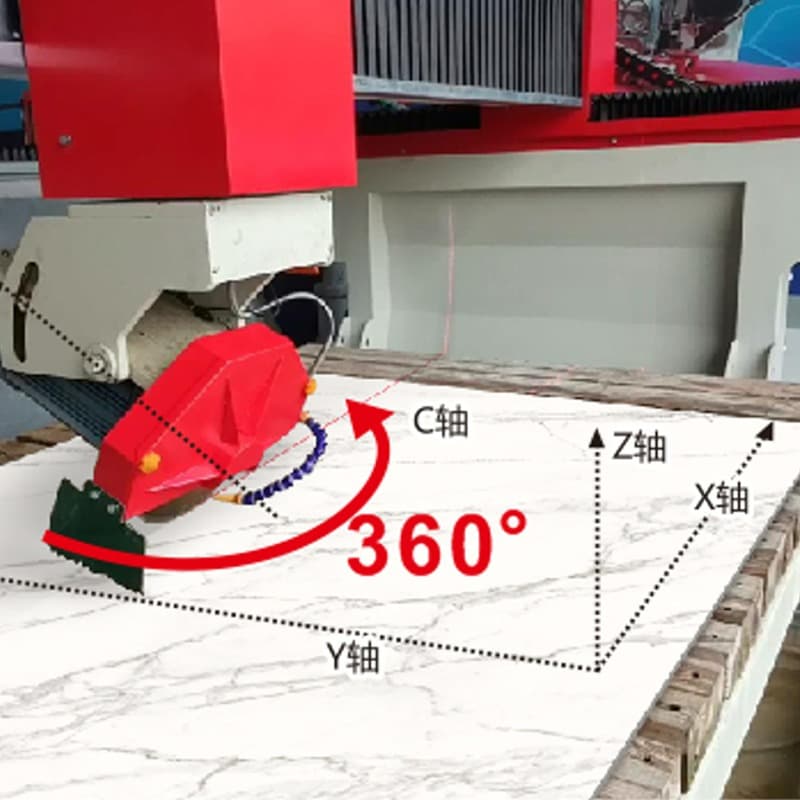

A 5-axis CNC Bridge Saw is a type of CNC equipment that is mostly utilized in the stone fabrication business. It is intended for precisely and intricately sculpting stone slabs such as granite, marble, and quartz. "5-axis" refers to the machine's capability to move and control cutting tools in five different axes simultaneously. These five axes are X, Y, Z, A, and C, each serving a specific purpose in the cutting process.

X-Axis: This axis controls the left-to-right movement of the cutting head.

Y-Axis: It manages the front-to-back movement of the cutting head.

Z-Axis: This axis controls the vertical movement of the cutting head.

A-Axis: It tilts the cutting head from 0 to 90 degrees, allowing for inclined and vertical cuts.

C-Axis: This axis rotates the cutting head 360 degrees, enabling intricate profile cuts.

Professional 5 Axis Bridge Saw For Sale

How Does It Work?

A 5-axis CNC Bridge Saw's operation begins with the preparation of a digital design or CAD (Computer-Aided Design) file that describes the intended cut or form. This file is then imported into the machine's control software, which interprets the design and translates it into precise movements of the cutting head.

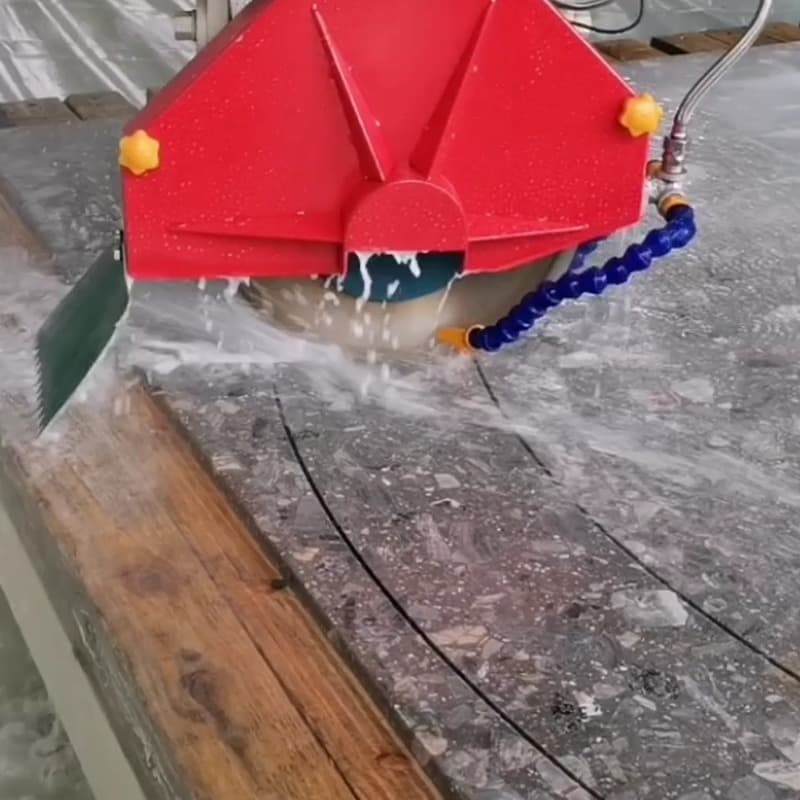

The cutting bed of the machine is securely attached to the stone slab to be cut. The cutting head of the 5-axis CNC Bridge Saw, which is equipped with a diamond-tipped blade, is positioned above the slab. As the machine starts, it precisely moves the cutting head in all five axes to make the required cuts. This multidirectional movement allows the machine to perform a wide range of cuts, from simple straight lines to highly complex 3D profiles and even undercuts, which are challenging to achieve with traditional cutting methods.

The CNC control software guarantees that each cut is completed with remarkable precision and consistency, resulting in little waste and maximum material yield. Additionally, the 5-axis CNC Bridge Saw can make cuts at different angles, ensuring that the finished pieces fit together seamlessly in intricate designs like countertops, sculptures, and architectural elements.

Industrial CNC Bridge Saw Suppliers

Conclusion

The 5-Axis CNC Bridge Saw is a testament to the transformative power of technology in manufacturing. It has revolutionized the stone fabrication industry by providing unmatched precision, efficiency, and versatility in the cutting and shaping of stone materials. As one of the famous Bridge saw cutting machine suppliers in China, AITAO is devoted to providing high-quality cutting machines including 5-axis CNC bridge saw machines. Please feel free to contact us!