In the world of manufacturing and construction, precision and efficiency are paramount. One technological marvel that has revolutionized the way stone and other hard materials are cut is the Bridge Cutting Machine. This complex piece of machinery has found a home in a variety of sectors, ranging from construction to monument manufacture, and has substantially improved the precision and speed of cutting operations. In this article, we will delve into what a Bridge Cutting Machine is.

What Is A Bridge Cutting Machine?

A Bridge Cutting Machine, also known as a Bridge Saw, is a specialized piece of equipment designed for cutting hard and brittle materials, primarily natural and engineered stone, granite, marble, and ceramics. The term "bridge" refers to the horizontal bridge-like framework that spans the worktable, supporting the cutting head and providing stability during cutting operations.

Bridge Saw Cutting Machine Suppliers

How Does It Work?

Bridge Cutting Machines utilize a combination of advanced technology and engineering to achieve precise and efficient cutting. Here's a simplified overview of the basic working principles:

Material Placement: The material to be cut is placed on a flat worktable beneath the bridge structure.

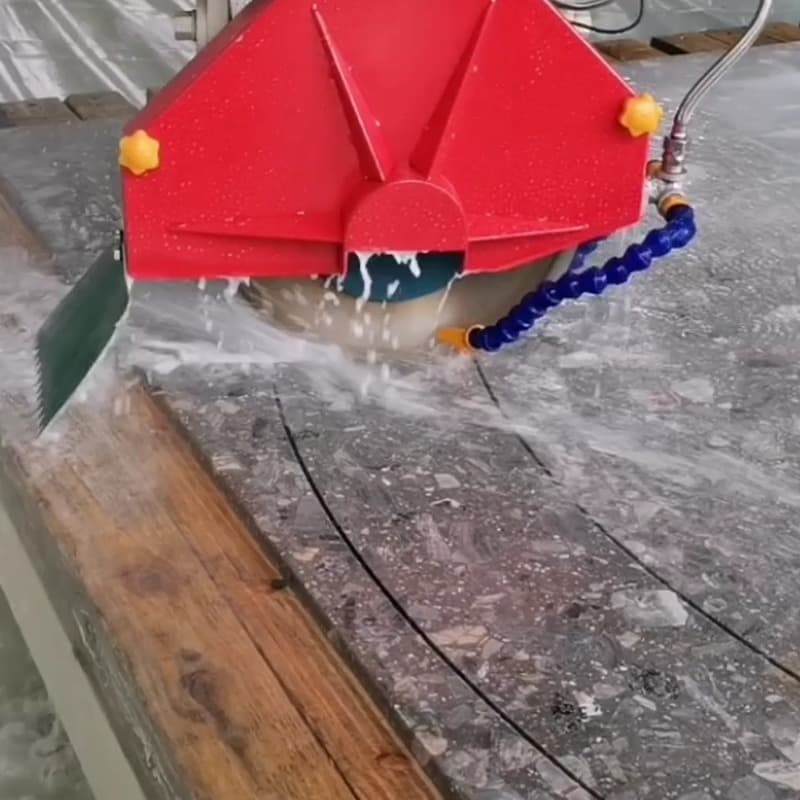

Precision Cutting Head: The cutting head, typically equipped with a diamond-tipped blade, is mounted on the bridge. Diamond blades are utilized for their extreme hardness and cutting accuracy.

Computer Numerical Control (CNC): Most modern Bridge Cutting Machines are equipped with CNC systems, which allow for precise and automated control of the cutting process. Operators may program the machine's computer with specified dimensions and patterns, assuring flawless cuts every time.

Cutting Process: The CNC system directs the movement of the cutting head as it moves over the bridge, creating accurate cuts according to the design. The high-speed rotation of the diamond blade allows for clean and efficient cuts through even the toughest materials.

Water Cooling: Water is often used to cool the cutting blade and suppress dust during the cutting process. This helps to extend the life of the blade and preserve cutting precision.

Professional CNC Bridge Saw Manufacturers

Benefits Of Bridge Cutting Machines

Bridge Cutting Machines, also known as Bridge Saws, have become essential tools in various industries that involve cutting hard and brittle materials such as natural and engineered stone, granite, marble, and ceramics. Here are some benefits of bridge cutting machines:

Precision Cutting: Bridge Cutting Machines are renowned for their exceptional precision. Equipped with advanced computer numerical control (CNC) systems, these machines can execute intricate cuts with accuracy down to fractions of a millimeter. This accuracy guarantees that the finished product fulfills all of the criteria, eliminating mistakes and material waste.

Efficiency: Efficiency is a key advantage of Bridge Cutting Machines. These machines are capable of high-speed cutting, significantly reducing production times compared to manual cutting methods. This efficiency correlates to cost savings because reducing operations takes less work and time to execute.

Versatility: Bridge Cutting Machines are incredibly versatile. They can accommodate a wide range of materials, including different types of stone, ceramics, and even glass. They may also be programmed to make a variety of cuts and patterns, making them appropriate for a wide range of applications across industries.

Improved Safety: The automation of cutting processes in Bridge Cutting Machines enhances workplace safety. By minimizing the need for manual intervention, the risk of accidents and injuries associated with traditional cutting methods is significantly reduced. Integrated water cooling systems frequently shield operators from dust and debris.

Enhanced Productivity: Bridge Cutting Machines considerably increase efficiency in manufacturing and construction operations due to their capacity to function constantly and effectively. This enhanced productivity may result in faster project completion and higher corporate profitability.

Cost-Effective Production: Bridge Cutting Machines can result in significant cost reductions over time. Because of their efficiency, accuracy, and decreased material waste, they are a cost-effective investment for organizations.

5 Axis CNC Bridge Saw Manufacturers

Conclusion

The Bridge Cutting Machine is a testament to the fusion of engineering precision and technology's transformative power. It has become a vital tool in a wide range of sectors where precision and efficiency are critical. If you are looking for a bridge cutting machine, AITAO can help you. We offer a wide range of cutting machines including waterjet cutting machines. Please feel free to contact us for more details!