CNC (Computer Numerical Control) cutting and laser cutting are two common precision cutting and fabrication processes that have transformed sectors such as manufacturing, aerospace, automotive, and many others. While both methods are used to create precise and intricate cuts in a wide range of materials, they employ distinct techniques and technologies. In this article, we will delve into the key differences between CNC cutting and laser cutting.

Cutting Mechanism

CNC Cutting: CNC cutting encompasses a wide array of techniques, each employing different cutting tools suited to specific materials and applications. For instance, routers are ideal for wood and plastics, while plasma cutters excel with metals. Waterjet cutting cuts through a range of materials by using a high-pressure spray of water combined with abrasive compounds. Each of these tools operates under computer control, with precise coordinates and cutting paths determined by a CAD (Computer-Aided Design) file.

Laser Cutting: Laser cutting operates on the principle of focused, high-energy laser beams. The laser beam, usually a CO2 or fiber laser, is directed at the material's surface, causing localized heating and vaporization. This precise and controlled process results in clean, sharp cuts. Because of the laser's capacity to cut elaborate designs with incredibly fine details, it is a popular choice for applications requiring precision and intricacy.

Material Compatibility

CNC Cutting: CNC cutting can work with a variety of materials, making it a versatile option. Metals (steel, aluminum), polymers (acrylic, PVC), wood, foam, composites, and even ceramics are often employed. The adaptability of CNC machines lies in their ability to switch out tools and configurations to match the material being worked on.

Laser Cutting: Laser cutting is highly effective with materials like metals (particularly stainless steel, aluminum, and mild steel), acrylic, wood, leather, fabric, and certain plastics. However, laser cutting may not be as effective for highly reflective or transparent materials since the laser beam may struggle to penetrate or reflect off these surfaces.

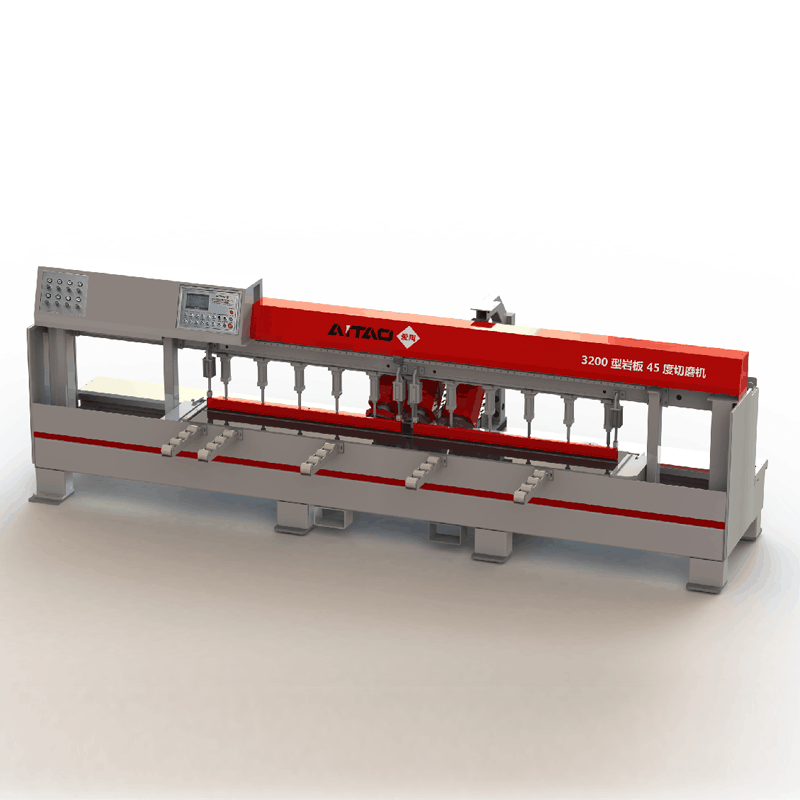

Professional Bridge Cutting Machine Manufacturers

Precision And Accuracy

CNC Cutting: The precision and accuracy of CNC cutting are determined by factors such as the quality of the cutting tool, the machine's calibration, and the operator's skill. While CNC machines may reach great levels of precision, they may not always match laser cutting's micron-level precision.

Laser Cutting: Laser cutting is known for its high precision and accuracy. It has a high degree of repeatability, making it excellent for applications requiring consistency and tight tolerances. For example, in the aerospace industry, laser-cut components are used extensively for their accuracy and reliability.

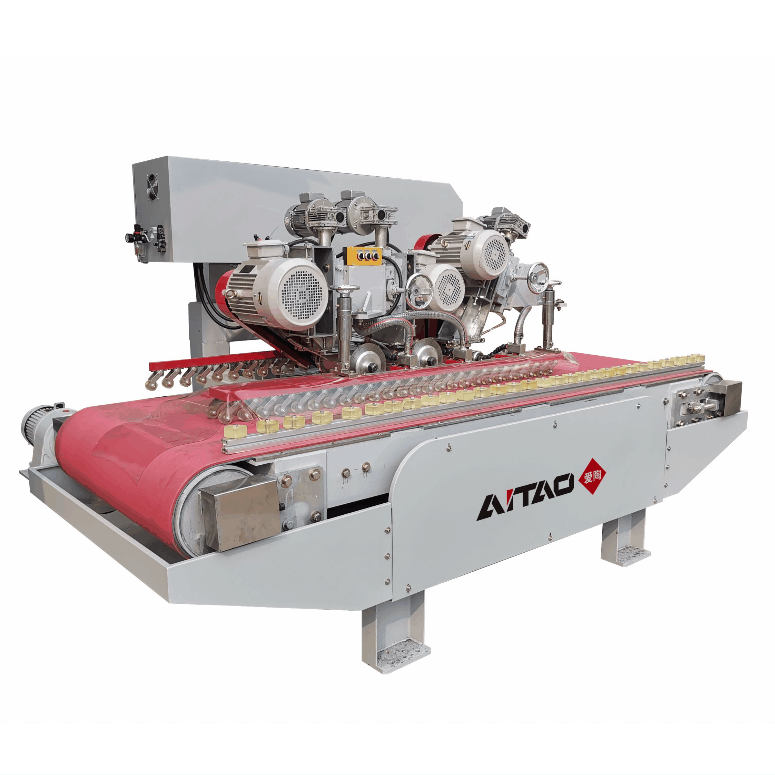

CNC Machine For Stone Edge Grinding

Speed And Efficiency

CNC Cutting: The speed of CNC cutting varies depending on the material, tool, and complexity of the design. While it is typically efficient, it may be slower than laser cutting, particularly for elaborate patterns and thin materials. CNC machines excel at jobs that need mass material removal or shaping.

Laser Cutting: Laser cutting is well-known for its speed and efficiency. The laser beam's ability to swiftly traverse the material makes it ideal for mass production where high throughput and quick turnaround are required. This efficiency extends to cutting intricate patterns, as laser cutting requires minimal tool changes and setup time.

Conclusion

Both CNC cutting and laser cutting are valuable tools in the realm of precision manufacturing and fabrication. Understanding these differences can help businesses and individuals make informed decisions. AITAO, one of the famous cutting machine suppliers, offers a wide range of cutting machines. Please consider us and try our high-quality products!