Computer Numerical Control (CNC) technology has transformed the way materials such as stone are molded and carved in modern industry and construction. The CNC stone cutting machine stands out as a prime example of this technological advancement, bringing unparalleled precision and efficiency to the world of stone processing. In this article, we delve into the inner workings of these sophisticated machines, exploring the processes that make them indispensable in the stone industry.

What Is The CNC Technology?

CNC machines operate under computer control, where pre-programmed instructions guide the movement of the cutting tools. In the case of stone cutting, these machines provide exact control over the cutting process, producing elaborate and detailed designs.

How Does The CNC Stone Cutting Machine Work?

Here are the key steps of CNC stone cutting machine work:

Design And Programming

The first step in a CNC stone cutting project is to create a digital design using Computer-Aided Design (CAD) software. This design acts as a template for the stone cutting process, describing each cut, curve, and contour. Once the design is finalized, it is converted into a CNC-compatible program using Computer-Aided Manufacturing (CAM) software. This program provides the instructions necessary for the CNC machine to execute the design accurately.

Machine Setup

Before the cutting process begins, the stone slab is securely fixed onto the machine's worktable. The CNC operator maintains appropriate alignment and placement by following the design's dimensions and standards. Additionally, the cutting tools are selected based on the type of stone and the intricacy of the design.

Toolpath Generation

The CAM software generates a toolpath, which is the route the cutting tool will follow to shape the stone according to the design. This toolpath is designed for efficiency and precision, taking into account tool speed, feed rate, and spindle rotation.

Cutting Process

Once the machine is set up and the toolpath is generated, the CNC stone cutting machine begins its precise operation. The cutting tools, often diamond-tipped for durability, slice through the stone surface by the programmed instructions. The CNC machine's ability to control the cutting depth, speed, and direction with exceptional accuracy ensures that the final product reflects the intricacies of the digital design.

Finishing Touches

After the basic cutting is completed, the stone may go through further finishing operations, such as polishing or smoothing the surfaces. CNC machines can be programmed to perform these secondary operations, contributing to the overall efficiency of the stone processing workflow.

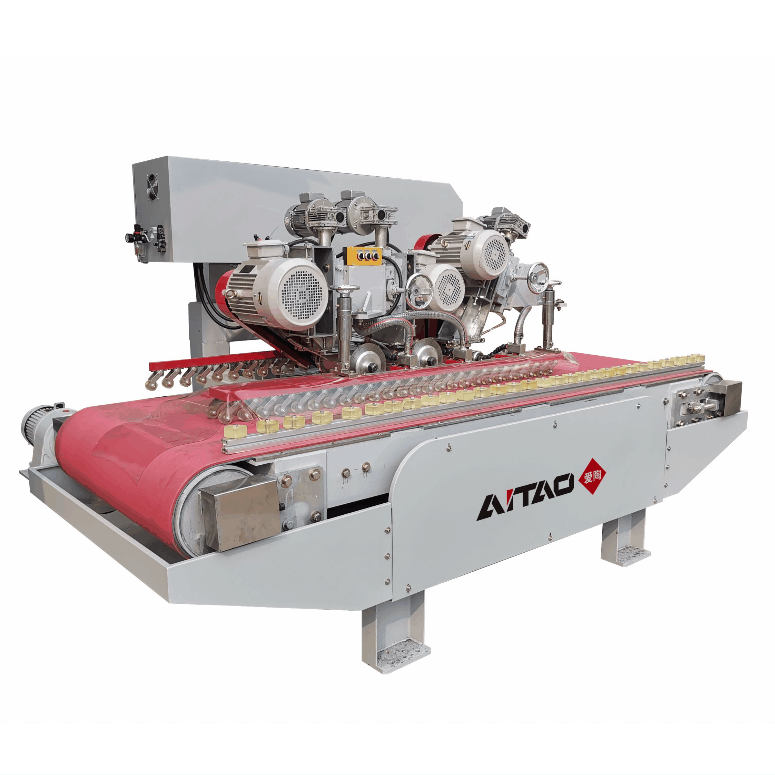

Edge Grinding For Sintered Stone

Advantages Of CNC Stone Cutting

Incorporating CNC stone cutting machines into the stone processing sector has several benefits, transforming the way the stone is formed, carved, and used in diverse applications.

Precision And Accuracy

One of the most significant advantages of CNC stone cutting is the unparalleled precision and accuracy it offers. These machines can execute elaborate patterns with microscopic precision, guaranteeing that the finished product accurately reflects the computer design. The level of precision achieved with CNC technology surpasses what can be accomplished through traditional manual methods, guaranteeing a level of consistency that is vital for high-quality stone products.

Efficiency And Speed

CNC stone cutting machines work with incredible efficiency and speed. The automation of the cutting process reduces the need for manual intervention, allowing for continuous and efficient manufacturing. The precise control over cutting tools' movements, coupled with optimized toolpaths, ensures that projects are completed in a fraction of the time it would take using traditional methods. This efficiency not only enhances productivity but also allows for the rapid realization of complex and intricate designs.

Reduced Material Waste

CNC technology minimizes material waste, a crucial factor in the cost-effectiveness and sustainability of stone processing. The accuracy of the cutting process means that each movement of the cutting tool contributes to the finished product, eliminating waste. This not only has economic benefits but also aligns with environmental considerations, making CNC stone cutting a more sustainable option compared to traditional methods that often result in significant material losses.

Consistency And Repeatability

CNC stone cutting machines excel at providing consistent and reproducible outcomes. After a pattern is created, the CNC machine can repeat it exactly across several stone pieces. This level of consistency is essential, especially in large-scale projects where uniformity is a key requirement. The ability to reproduce intricate designs with precision ensures that every stone product meets the desired specifications, contributing to a cohesive and professional result.

Complex Designs And Intricate Patterns

CNC stone cutting machines unlock the potential for creating complex and intricate designs that would be challenging or impossible to achieve manually. The accuracy of the cutting equipment, along with the flexibility of digital design, enables the creation of intricate patterns, complex reliefs, and artistic aspects in stone.

Automation And Labor Efficiency

The automation inherent in CNC stone cutting significantly reduces the reliance on skilled manual labor for the cutting process. This not only addresses labor shortages but also reduces the impact of human mistakes. CNC machines can operate continuously, requiring minimal human intervention, and freeing up skilled craftsmen to focus on more intricate or specialized tasks within the stone processing workflow.

Adaptability To Various Stone Types

CNC stone cutting machines can work with a variety of stone kinds, ranging from soft and porous to hard and solid. The versatility of these machines allows for the processing of diverse materials without compromising on precision or efficiency. Whether working with marble, granite, limestone, or other types of stone, CNC technology ensures that the cutting process is tailored to the specific characteristics of each material, resulting in optimal outcomes.

Conclusion

The CNC stone cutting machine stands as a testament to the marriage of technology and craftsmanship in the stone industry. As technology advances, CNC stone cutting machines are expected to play an increasingly important role in determining the future of stone processing. As a leading CNC machine supplier, AITAO offers a variety of CNC machines including CNC waterjet cutting machines, CNC stone cutting machines, etc to fit different applications. Visit our site today to learn more about what we offer.