Waterjet cutting, a technology renowned for its precision and versatility, serves as a cornerstone in modern manufacturing and design. By harnessing the power of a high-pressure water stream, often mixed with abrasive particles, this method can slice through a multitude of materials with remarkable accuracy and minimal thermal impact. The adaptability of waterjet cutting makes it invaluable across various sectors, including aerospace, automotive, art, architecture, and beyond. This article delves into the widespread applications of waterjet cutting and water jet cutting applications, showcasing its critical role in shaping industries and its contribution to innovation.

Aerospace Applications of Waterjet Cutting

In the realm of aerospace, where precision and quality are non-negotiable, waterjet cutting emerges as a pivotal technology. It's extensively employed for cutting high-strength materials like titanium, advanced composites, and aluminum—materials integral to aerospace engineering. The challenge of machining titanium, known for its toughness, is elegantly met by waterjet cutting, which ensures precise cuts without significant heat generation, thus mitigating the risk of warping or material distortion. The technology's ability to handle complex shapes and intricate designs makes it indispensable for fabricating critical aerospace components, from fuselage parts to intricate engine elements.

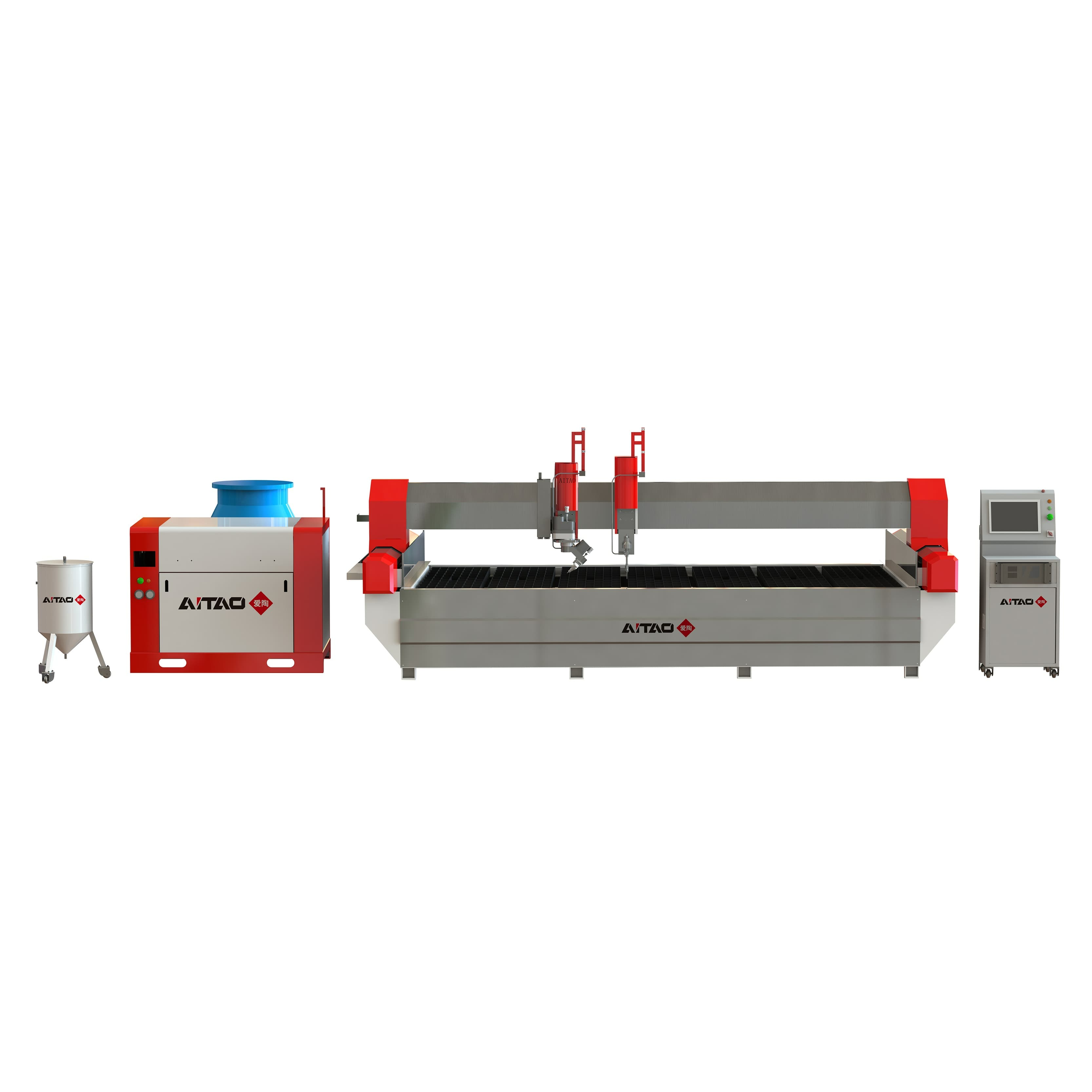

Waterjet Cutting Machine For Metal

Enhancing Automotive Manufacturing with Waterjet Cutting

Waterjet cutting stands as a transformative force in automotive manufacturing, offering unparalleled precision for a spectrum of applications. Its pivotal role in gasket production exemplifies this, where the technology's exactitude ensures leak-proof sealing in engines and other vehicle systems. Beyond gaskets, waterjet cutting is instrumental in shaping dashboards, chassis components, and aesthetic features, enhancing both the functionality and aesthetics of automotive parts. The method's precision not only upholds the structural integrity of these components but also elevates their visual appeal, underscoring the technology's comprehensive impact on automotive design and manufacturing.

Revolutionizing Architectural Design with Waterjet Cutting

Waterjet cutting has ushered in a new era for architectural design, facilitating the creation of bespoke and complex elements that elevate the aesthetic and luxury of spaces. Its application in flooring design is particularly noteworthy, where the technology precisely cuts through marble, granite, and other premium materials to craft intricate patterns and mosaics. These waterjet-cut designs are not limited to floors but extend to walls, where they form captivating murals and decorative elements, enhancing both interior and exterior environments. The versatility of waterjet cutting empowers architects to explore and integrate a diverse range of materials, broadening the horizons of architectural creativity and innovation.

Artistic Creations

Waterjet cutting, also known as water jet cutting, is revolutionizing the art world with its unmatched precision and versatility. Artists can now achieve intricate designs in various materials such as metal, glass, and stone, which were previously difficult or impossible to cut with traditional methods. This technology allows for the creation of detailed sculptures, metal inlays, and even complex stained glass pieces. By using waterjet cutting, artists can push the boundaries of their creativity, bringing their unique visions to life with remarkable accuracy and detail.

Medical Devices

Precision and biocompatibility are critical in the production of medical devices and implants. Waterjet cutting is used extensively to manufacture components for items like orthopedic implants, surgical instruments, and medical device housings. It enables producers to work with biocompatible materials like titanium and stainless steel, guaranteeing that the finished products fulfill the strict quality and safety requirements necessary in the medical profession.

Automated Waterjet Cutting In Ceramic Tile Production

Electronics Manufacturing

Miniaturization and accuracy are critical in electronics production. Waterjet cutting is used to accurately cut materials such as printed circuit boards (PCBs) and silicon wafers. This technology enables manufacturers to create intricate PCB designs with precision, improving the performance and functionality of electronic devices. Waterjet cutting also reduces waste in the manufacturing process, contributing to cost-efficiency.

Food Industry

Waterjet cutting has found an unexpected yet valuable application in the food industry. It is used to cut a wide range of food products, including vegetables, meats, and baked goods. The method has a number of advantages, including reduced product waste and improved cleanliness. Waterjet systems can cleanly and accurately cut food products, maintaining uniform portion sizes and eliminating the danger of contamination.

Conclusion

Waterjet cutting technology has become an indispensable tool across a wide range of industries due to its precision, versatility, and ability to cut various materials without heat distortion. As a leading electromechanical equipment company, AITAO offers various electromechanical equipment including a waterjet cutting machine. If you are interested in it, get in touch with us now!