In the bustling arena of modern manufacturing, waterjet cutting has soared to prominence, offering a level of precision and versatility akin to an artist's brush in the hands of skilled fabricators. Harnessing a high-pressure cascade of water, at times fused with gritty abrasive companions, this method has etched its mark in diverse sectors. From the exacting world of aerospace to the creative studios of fine arts, the allure of waterjet cutting is both broad and deep. Let's slice through the hype and explore the concrete benefits that elevate waterjet cutting to a cut above the rest.

Precision And Intricacy

Imagine carving out a design so intricate that it feels like the whisper of a butterfly's wing on metal or stone—that's the finesse waterjet cutting brings to the table. With the power of a focused water stream, often boosted by abrasive particles, it sculpts complex patterns and shapes with the kind of precision that's non-negotiable in fields like aerospace. Here, even the smallest deviation can send things spiraling—quite literally. It's not just about getting the job done; it's about achieving a level of artistry in each cut.

Versatility

Waterjet cutting's versatility is its superpower, handling a kaleidoscope of materials with the ease of a chameleon changing colors. Its secret? The absence of heat. While other cutting methods like laser or plasma can singe and warp, waterjet cutting keeps it cool, ensuring materials from delicate foams to robust metals remain unscathed and true to form.

Minimal Heat-Affected Zone

The beauty of waterjet cutting lies in its ability to play it cool—literally. Traditional techniques can get hot-headed, warping materials and altering their essence. But waterjet cutting? It's the Zen master of the cutting world, maintaining the material's integrity and ensuring that what you designed on-screen is exactly what takes shape in the real world.

Reduced Machining Time

Speed is the name of the game, and waterjet cutting is sprinting ahead. By slashing through materials at breakneck speeds and reducing the need for secondary finishing touches, it's not just shaving off hours—it's cutting down costs. And in an industry where time is as precious as the materials being shaped, that's nothing short of gold.

Safety

In the dance of manufacturing, safety leads. Waterjet cutting takes this to heart, keeping its distance and cutting without contact. No sparks, no flames, just a safe space for operators to work their magic. And with no hazardous fumes crashing the party, it's a breath of fresh air for everyone involved.

Composite Material Waterjet Cutting

Environmental Friendliness

In an era where sustainability is at the forefront of industrial practices, waterjet cutting stands out as an eco-friendly option. Its operation produces minimal waste since the water and abrasive materials employed in the cutting process can be reclaimed and cycled back into the system. This form of closed-loop recycling diminishes both water consumption and waste generation, underscoring waterjet cutting as an environmentally responsible choice for modern manufacturing needs.

Conclusion

Waterjet cutting has several advantages, including precision, adaptability, environmental sustainability, safety, and time efficiency. Its ability to cater to diverse industries, handle a wide range of materials, and maintain material integrity sets it apart as a groundbreaking technology.

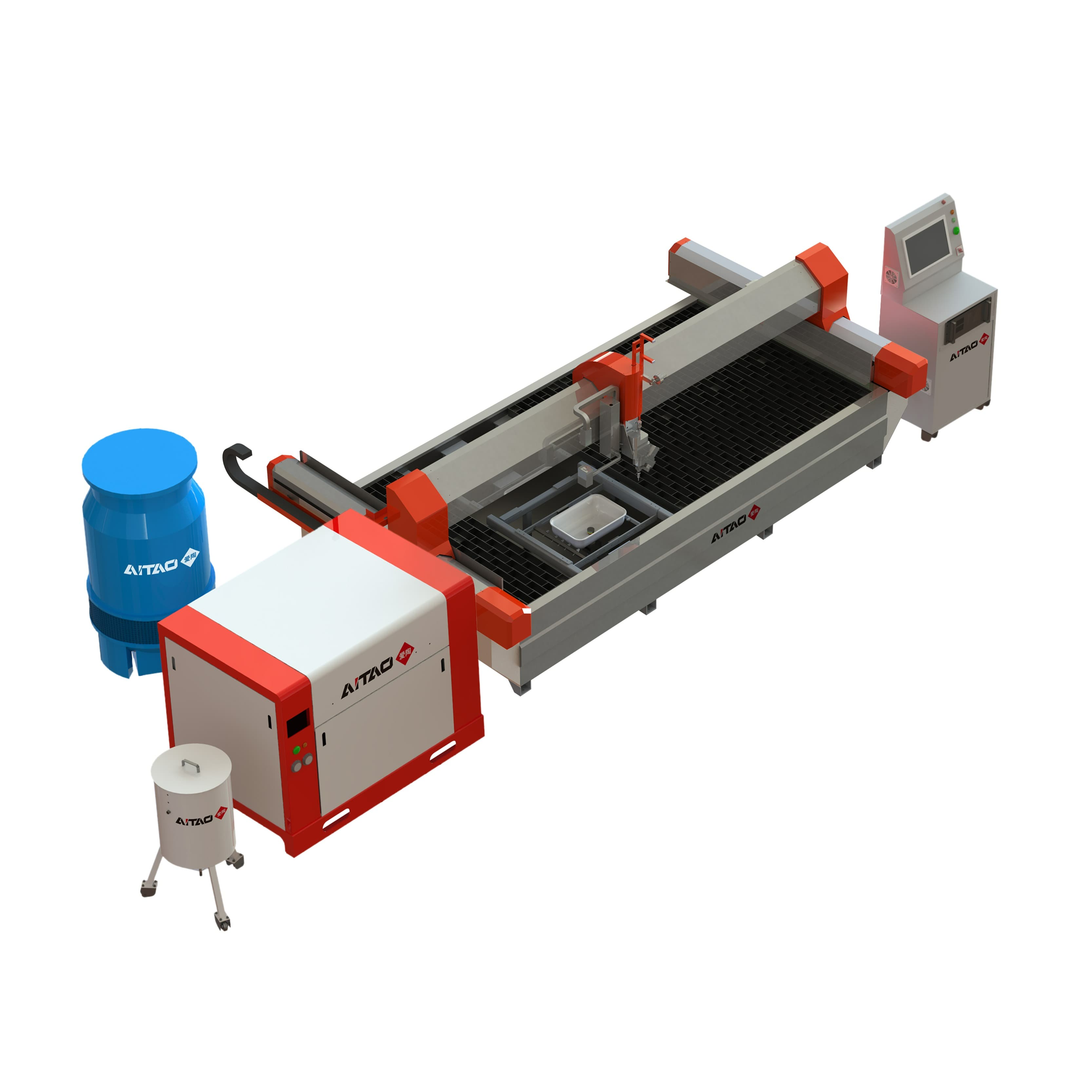

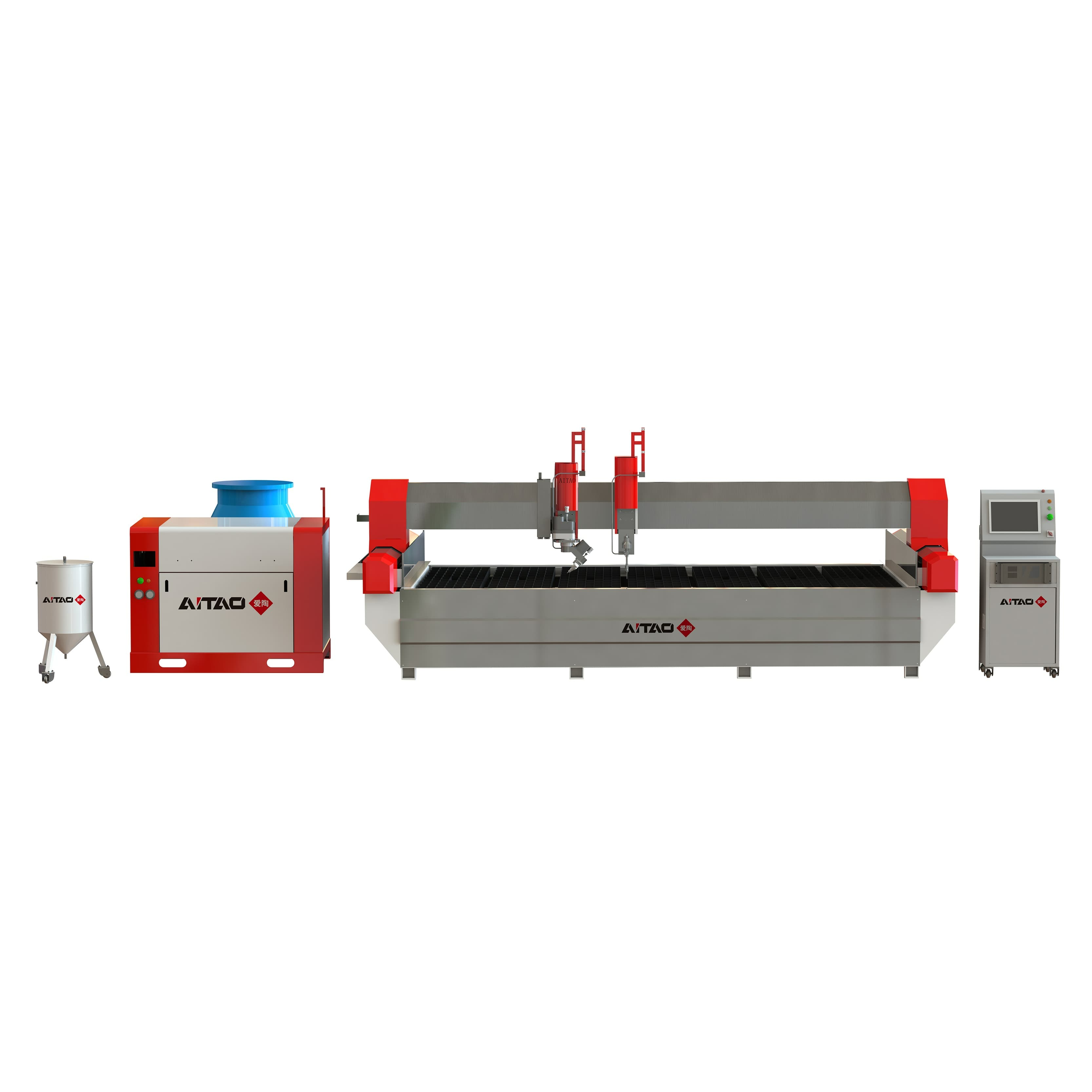

If you are looking for a high-quality waterjet cutting machine, AITAO is ideal for you. Please feel free to contact us at fsaitao789@outlook.com for further information about our top-quality waterjet cutting machines!

FAQs

1. What materials can be cut with waterjet cutting technology?

Waterjet cutting is renowned for its material versatility, capable of slicing through a diverse range of substances with precision. It can efficiently cut metals such as steel and aluminum, natural materials like stone and marble, as well as composites, glass, and ceramics. Its gentle approach even allows for the cutting of softer materials, including rubber, foam, and plastics, without causing any thermal distortion or damage.

2. How does waterjet cutting compare to laser cutting in terms of precision and material integrity?

While both waterjet and laser cutting offer high levels of precision, waterjet cutting has the distinct advantage of preserving the material's integrity. Unlike laser cutting, which uses heat and can alter a material's properties around the cut, waterjet cutting is a cold-cutting process. This means there's no heat-affected zone (HAZ), making it ideal for materials that are sensitive to high temperatures or prone to warping, such as thermoplastics and metals.

3. Is waterjet cutting an environmentally friendly process?

Yes, waterjet cutting is considered to be an environmentally friendly cutting process. It minimizes waste by utilizing water and abrasive materials that can be recycled and reused within the system. This method of cutting does not produce hazardous materials or significant amounts of airborne dust, making it a cleaner alternative to other cutting methods. Additionally, because it's a cold-cutting process, it eliminates the risks associated with fumes and gases that are often generated by thermal cutting processes.