In the ever-evolving landscape of manufacturing, precision and efficiency are paramount. Traditional machining methods have paved the way for advanced technologies, and one such innovation that has revolutionized the manufacturing industry is 5-axis machining. This advanced approach enables unparalleled flexibility and precision in the creation of complicated components. In this article, we will explore the reasons why manufacturers are increasingly turning to 5-axis machining to meet the demands of modern production.

Multi-Axis Flexibility

Precision in Complex Geometries

When working with delicate geometries and complex curves, the inherent flexibility of 5-axis machining provides for unsurpassed precision. Traditional machining processes may struggle with accessing certain angles or features, but 5-axis machining ensures that the cutting tool can approach the workpiece from any direction, enabling the production of highly detailed and precisely shaped components.

Single Setup Efficiency

By incorporating two additional rotational axes, A and B, manufacturers can significantly reduce the need for multiple setups. This not only speeds up the machining process but also reduces the difficulties involved with manually aligning and adjusting the workpiece. The result is a more efficient workflow, reducing the likelihood of errors and improving overall production time.

Enhanced Precision And Accuracy

Optimal Tool Orientation

The capacity to precisely adjust the orientation of the cutting tool is a significant benefit of 5-axis machining. This appropriate tool orientation enables continuous contact with the workpiece, which results in tighter tolerances and better surface finishes. Industries that demand exacting standards, such as aerospace and medical manufacturing, benefit significantly from this heightened level of accuracy.

Dynamic Machining Conditions

In 5-axis machining, the cutting tool can adapt to the contours of the workpiece dynamically. This versatility enables the preservation of ideal cutting conditions, resulting in a smoother machining process. The dynamic nature of the machining conditions contributes not only to precision but also to improved overall efficiency.

Reduced Setup Time

Streamlining Production Workflow

Traditional machining methods often involve time-consuming setups and repositioning of the workpiece to access different surfaces. With 5-axis machining, the need for multiple setups is minimized, streamlining the production workflow. Reduced setup times translate to higher productivity, making 5-axis machining ideal for high-volume production runs.

Minimizing Error Risks

Manual repositioning increases the likelihood of alignment errors, which may result in faults in the final output. The reduced setup time associated with 5-axis machining not only accelerates production but also minimizes the opportunities for human error, contributing to a more reliable and consistent manufacturing process.

Improved Tool Life

Shorter Cutting Tools

5-axis machining allows for the use of shorter cutting tools without sacrificing performance. The benefits are twofold: shorter tools reduce tool deflection and enhance precision, and the reduced length contributes to improved rigidity, extending tool life. This optimization of tool utilization leads to cost savings over time, making 5-axis machining a good tool management investment.

Consistent Cutting Conditions

The multi-axis capability guarantees that the cutting tool maintains a constant cutting speed and chip load throughout the machining operation. This consistency plays a crucial role in minimizing wear and tear on the tool, extending its lifespan, and reducing the frequency of tool replacements, ultimately contributing to lower operational costs.

Expanded Design Possibilities

Overcoming Design Constraints

5-axis machining empowers engineers and designers to push the boundaries of what is achievable. Complex shapes, intricate contours, and undercuts that were once challenging or impossible to manufacture using traditional methods become feasible. This increased design flexibility encourages innovation by allowing the fabrication of previously restricted components due to manufacturing restrictions.

Innovation in Lightweight Structures

In industries like automotive and aerospace, where lightweight structures are essential, 5-axis machining opens up new avenues for designing intricate and lightweight components. The capacity to precisely design complicated geometries aids in the creation of high-performance, fuel-efficient vehicles and airplanes.

Cost-Effective Production

Long-Term Cost Savings

While the initial investment in 5-axis machining is expensive, the long-term cost reductions are tremendous. Reduced setup time, enhanced tool life, and optimized manufacturing processes all contribute to overall cost-effectiveness. Manufacturers can produce high-precision components with fewer resources, making 5-axis machining a strategic choice for those aiming to optimize operational costs.

High-Volume Production Efficiency

5-axis machining provides exceptional productivity for sectors that require high-volume manufacturing of complicated products. The ability to create complicated components in a single setup minimizes labor expenses associated with manual repositioning and setup changes. The economies of scale achieved through efficient 5-axis machining make it a cost-effective solution for meeting the demands of large-scale production.

Conclusion

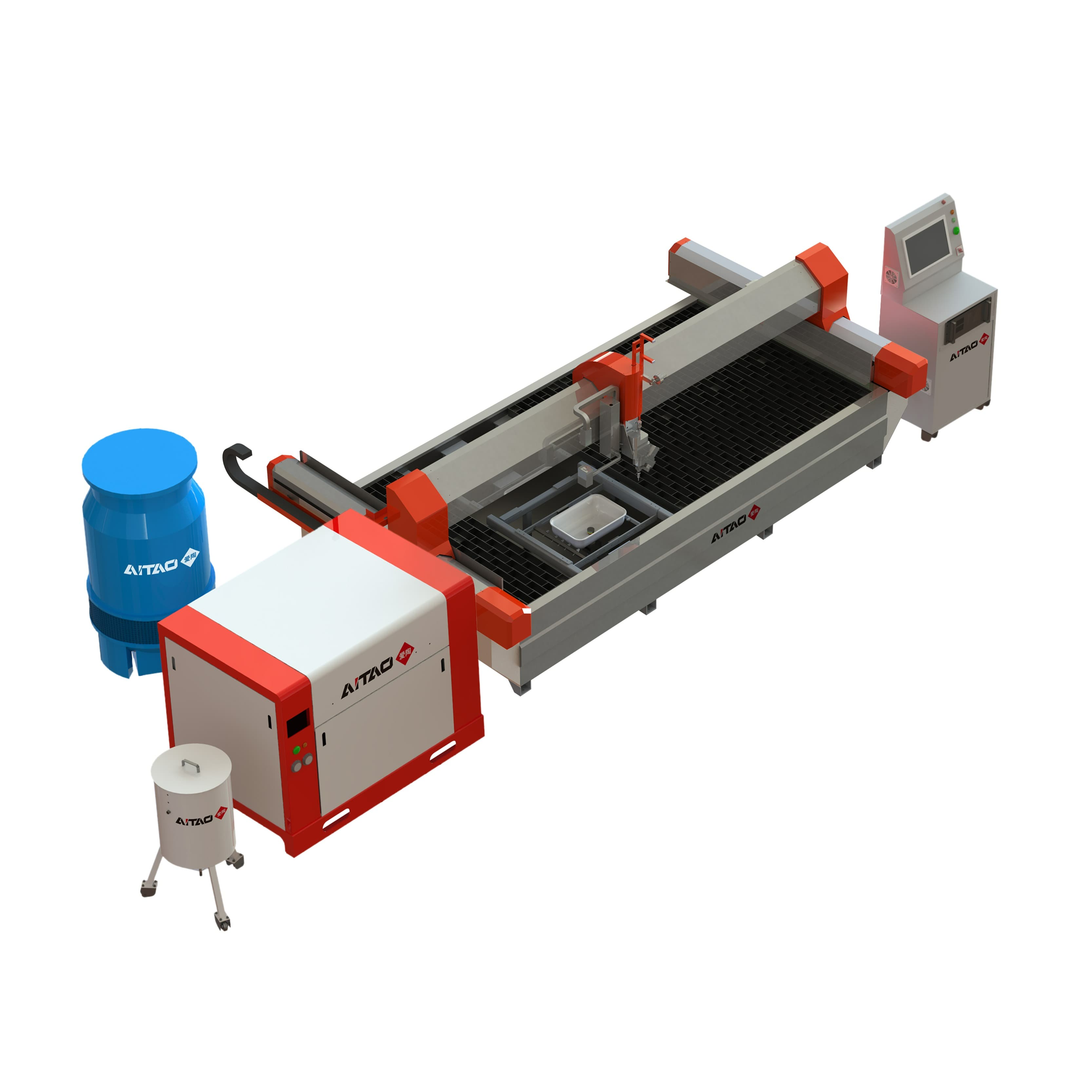

In conclusion, the benefits of 5-axis machining extend far beyond its initial implementation cost. If you are looking for 5-axis machining machines, AITAO is your good choice. We specialize in 5-axis waterjet cutting machines, Five-axis CNC bridge cutting machines, etc. Please feel free to browse our website for more product details.

FAQs

1: How does 5-axis machining differ from traditional 3-axis machining?

Answer:

Traditional 3-axis machining operates along the X, Y, and Z axes, allowing for cutting in three dimensions. In contrast, 5-axis machining introduces two additional rotational axes (A and B), providing unparalleled flexibility. This means that the cutting tool can approach the workpiece from any direction, enabling the machining of complex geometries with a single setup. While 3-axis machining is limited to straightforward cuts, 5-axis machining excels in producing intricate and highly detailed components.

2: What industries benefit the most from 5-axis machining?

Answer:

5-axis machining is particularly beneficial for industries that require high precision, complex geometries, and efficient production processes. Industries such as aerospace, automotive, medical manufacturing, and mold-making significantly benefit from 5-axis machining. The technology's ability to handle intricate designs and produce components with tight tolerances makes it an ideal choice for applications where precision is paramount. Moreover, the efficiency gains make 5-axis machining suitable for high-volume production scenarios.

3: Is the investment in 5-axis machining justified for small and medium-sized enterprises (SMEs)?

Answer:

While the initial investment in 5-axis machining equipment may seem substantial, the benefits it offers can justify the cost for many SMEs. The technology's efficiency in reducing setup times, improving tool life, and enabling the machining of complex components in a single setup contributes to long-term cost savings. SMEs with a focus on precision manufacturing or those looking to diversify their product offerings can find value in the versatility and efficiency that 5-axis machining provides. It's essential to evaluate the specific needs and production requirements of the business to determine the return on investment.